Tel/WhatsApp

Tel/WhatsApp

Cassava flash dryer

- Introduction

- Parameter

- Application

- Video

Introduction of cassava flash dryer:

Drying process is the last procedure for flour or starch production. Cassava flash dryer manufactured by DOING adopts new technology, which apply flash vaporization drying principle to save steam consumption and prevent gelatinization.

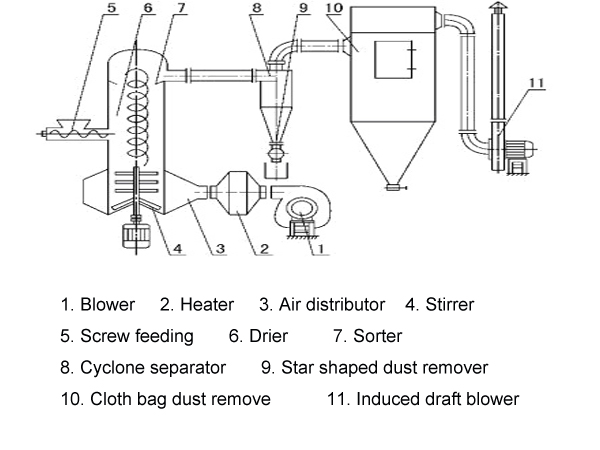

Cassava flash dryer structure

Cassava flash dryer structureThe working sequences of cassava flash dryer is as follows:

(1) Wet material is fed into the drying tube by conveyor and mixed with hot air, then divided into two suspensions and moving forward with high speed. The two suspension materials collides and enters into the fan after damped vibration(one part of cassava flash dryer). Bonded particles in wet starch get smaller after collision, vibration and fan crushing refinement, with increases specific surface area of materials so as to improve thermal efficiency, making free water vaporized quickly.

(2) Material is discharged into the vortex chamber of cassava flash dryer by the fan. After crushed by agitator, material would be sent forward. Wet material with relatively high humility and large gravity rotates along the outer wall at high speed, increasing the relative speed, enhancing heat transfer effect, and improving volumetric heat transfer coefficient. As a result, qualified material with appropriate water content would be discharged from center outlet.

(3) Material discharged from vortex chamber enters the first stage cyclone of cassava flash dryer, and dry starch goes into classification screen from bottom outlet, to be measured and packed. Other material with small amount light powder would enter the second stage cyclone for recycling, while wet air is discharged into atmosphere.

Cassava flash dryer

Cassava flash dryer

Performance characteristics of cassava flash dryer:

1) Short drying time, drying time is in commonly 1 ~ 2 seconds

2) Cassava flash dryer has a protective effect for the material, especially suitable for heat-sensitive materials.

3) High thermal efficiency, the drying time is short.

4) High output, large precipitation range.

5) Equipment is simple, cover an area of small, small investment.

6) Hot air source of cassava flash dryer: oil burner, gas type, coal-fired stove, steam heat exchanger.

- Introduction

- Parameter

- Application

- Video

DOING cassava flash dryer installtion in Tanzania

The main technical parameters of cassava flash dryer:

| Model | Power(kw) | Evaporation water(kg/h) | Labor | Starch capacity t/d (Moisture≤40%) |

| QZWG-5 | 14 | ≥100 | 2 | 5t |

| QZWG-10 | 23 | ≥200 | 3 | 10t |

| QZWG-20 | 43 | ≥400 | 3 | 20t |

| QZWG-30 | 50 | ≥600 | 4 | 30t |

| QZWG-50 | 75 | ≥1000 | 4 | 50t |

| QZWG-100 | 135 | ≥2000 | 5 | 100t |

Customized capacity of air-stream crash dryer machinesteam dryer is available.

- Introduction

- Video

- Introduction

- Application

- Video

The application of air-stream crash dryer machine:

1. Sweet potato starch production line

2. Potato starch production line

3. Cassava starch production line

4. Corn starch production line

5. Wheat starch production line

6. Rice starch production line

-

Entire chain of automatic fufu flour production line

Entire chain of automatic fufu flour production line

-

Functions and advantages of centrifuge sieve in potato starch purification line

Functions and advantages of centrifuge sieve in potato starch purification line

-

Manufacturing cycle time of Henan Jinrui's tapioca starch purification equipment

Manufacturing cycle time of Henan Jinrui's tapioca starch purification equipment

-

How Rasper Helps Increase the Efficiency and Productivity for Starch Production

How Rasper Helps Increase the Efficiency and Productivity for Starch Production

-

Advantages of Henan Jinrui's Flash Dryer for Cassava Flour and Starch Production

Advantages of Henan Jinrui's Flash Dryer for Cassava Flour and Starch Production

-

How Much Workshop Area is Needed for a Cassava Flour Plant? How to Place the Layout?

How Much Workshop Area is Needed for a Cassava Flour Plant? How to Place the Layout?

-

How to Ensure the Smooth Operation of Starch Processing Equipment?

How to Ensure the Smooth Operation of Starch Processing Equipment?

-

Common bottlenecks and solutions of cassava flour production

Common bottlenecks and solutions of cassava flour production

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others