Tel/WhatsApp

Tel/WhatsApp

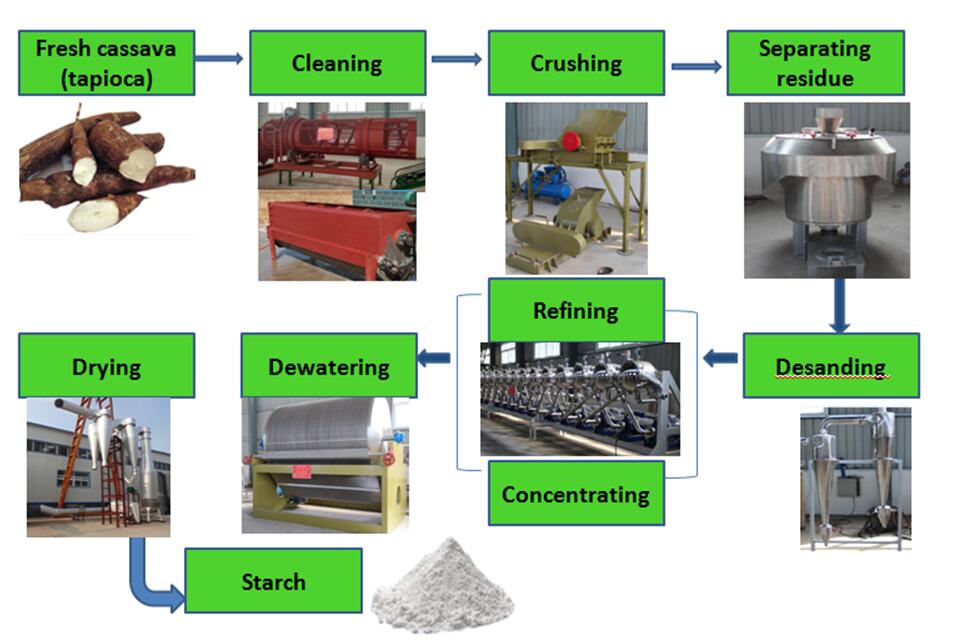

The process of tapioca starch production

Tapioca starch production line

We all know that ne kilogram of tapioca starch requires 4.4 kilograms of fresh cassava roots at its starch content of 25%.

This article mainly introduce process of tapioca starch production. In Thailand, the large-scale processing facilities with advanced tapioca starch production machines and technology have been replacing those primitive and small-scale factories. According to the studies, the tapioca starch production methods could be divided into two processes; traditional and modern.

Their details are as follows:

The traditional process, usually practiced in the small-scale factories, is able to separate starch from fresh cassava roots by crushing and then submerging the cassava under the water. The starch made through this process is inferior in quality. The process of this method has 9 steps as follows:

1. Weigh fresh tapioca roots to determine starch percentage.

2. Chop out the tails connected along with the roots before putting in the peeling devices.

3. Remove the peel and steep them in the cleansing well.

4. Put the clean ones in the chopper and grinder. Grind until they becomes fine particles and sediment them in the water. In this step, they appear as the slurry mix of starch,water, and fiber.

5. Filter the slurry to separate starch slurry from the fiber, however, the fiber still has some starch content that can be used as animal food.

6. Sediment the slurry in the wooden pail.

7. Dry the wet cake under the sun light on the yard.

8. Use the grindstone to grind the completely dried cake.

9. Pack in the bag.

-

Henan Jinrui delivers attieke processing equipment to the customer in Côte d'Ivoire

Henan Jinrui delivers attieke processing equipment to the customer in Côte d'Ivoire

-

Henan Jinrui Successfully Ships Cassava Flour Processing Line to Madagascar Client

Henan Jinrui Successfully Ships Cassava Flour Processing Line to Madagascar Client

-

Henan Jinrui Advanced Cassava Starch Processing Equipment Wins Over Nigerian Food Processor

Henan Jinrui Advanced Cassava Starch Processing Equipment Wins Over Nigerian Food Processor

-

Henan Jinrui Delivers Custom 1TPD Garri & Attieke Making Equipment to Benin

Henan Jinrui Delivers Custom 1TPD Garri & Attieke Making Equipment to Benin

-

Henan Jinrui Secures Order from Benin for 1-Ton Daily Garri and Attieke Processing Machines

Henan Jinrui Secures Order from Benin for 1-Ton Daily Garri and Attieke Processing Machines

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others