Tel/WhatsApp

Tel/WhatsApp

Principle of isolation of starch from potato

Potato starch is widely used in textile, petroleum mining, feed and food industries, especially the development of the international and domestic food market, which makes the demand of high precision potato starch increase, and potato starch has other natural properties that cannot be replaced by other starch, making it the first choice product of the starch industry. The demand of principle of isolation of starch from potato is increasing.

However industrial use of potato starch has been limited. The utility of potato starch can be increased by developing appropriate processing techniques to prepare potato starch with desirable properties. The isolation of starch from potato in China began in the 50s of the last century. After decades of development, the traditional workshops have been fully mechanized. The development of industry is improving the employment rate and promoting the development of agricultural economy. The principle of isolation of starch from potato on the following.

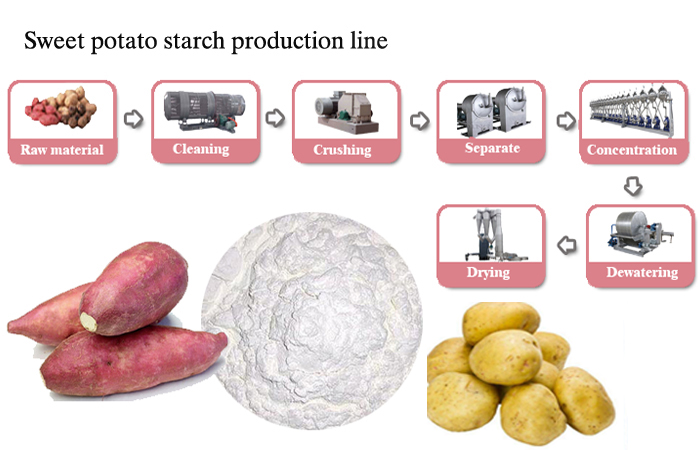

Potato starch isolation process

Cleaning and washing is the first section of the principle of isolation of starch from potato, Dry sieve can effectively remove dirt, sand and small stones, it has the ability to avoid sewage disposal. According to multiple spiral operation, rotary drum washing machine can remove silts and impurities from the surface of potato. This section also can be performed manually.

In the crushing section, Rasper is the filing and fragmentation machine and to improve the crushing rate and extraction rate. It has the features of modern design, compact structure, high speed, high rasping coefficient. This is the second section of the principle of isolation of starch from potato.

Potato cleaning machine-drum cleaner

In the screening section, centrifuge sieve is mainly used to separate the fiber and starch slurry. It is widely used in the extraction of corn\maize, wheat and tubers starch. The sieve basket is made of titanium plate, with laser punching processing. There are some advantages of the machine: low power consumption, stable operation and high starch extraction rate. Fine fiber sieve will be used in the section to get rid of fine fiber in crude starch. This is the principle of isolation of starch from potato in the screening section.

Potato starch isolation production process

In the concentrating section, first, hydro cyclone station will remove fiber, protein and cell to further process starch milk. The hydro cyclone pipe made of strengthened nylon. Second, vacuum filter is a solid-liquid separation machine which is formed by vacuum pressure and vacuum filtration. It is the negative pressure formed at the outlet of filtrate as a driving force for filtration. The basic principle of vacuum dehydrator for starch making is that under the action of vacuum negative degree(0.04-0.08MPa), the liquid in suspension is withdrawn through filter cloth, while solid particles are withheld. The guideline is one of the principle of isolation of starch from potato.

In the drying section, the flash dryer not only applies to various kinds of potato starch drying, but also for corn and wheat starch drying. The machine is able to reduce the loss of starch depends on negative pressure system and guarantee the high standards of final project.

Doing Company air flash dryer for starch

In the sieving section, the function of starch sieve is classification the starch in accordance with the different mesh. The demand for starch in the international market is increasing and consumption is increasing. The total demand for potato starch is increasing year by year. It is not late to know the principle of isolation of starch from potato and start the potato starch processing.

Above all, this is the complete introduction of the principle of isolation of starch from potato.

-

Cassava transformation into gari granules facility shipped to Guyana

Cassava transformation into gari granules facility shipped to Guyana

-

15tph full set cassava chips processing facility was shipped to Laos

15tph full set cassava chips processing facility was shipped to Laos

-

Cassava mill and garri sieving plant designed for standardized garri production was dispatched to Nigeria

Cassava mill and garri sieving plant designed for standardized garri production was dispatched to Nigeria

-

How is tapioca flour produced?

How is tapioca flour produced?

-

How profitable is garri processing?

How profitable is garri processing?

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others