Tel/WhatsApp

Tel/WhatsApp

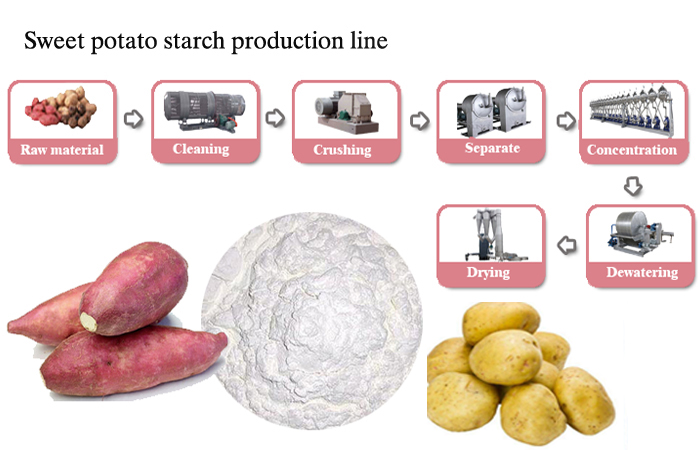

Potato starch processing technology

- Introduction

Automatic potato starch processing technology, mainly composed by 5 parts, that is cleaning system, compound crushing system, squeeze and filter system, concentration and purification system, dewatering and drying system. This potato starch processing line combined the cleaning, crushing, concentration, purification and drying, realized the automatic continuous operation of potato starch production. Following is its main features:

Potato starch processing

1. Our potato starch processing equipment adopts unique cleaning crushing filtering system, completely with manual principle design, compared with the equipment technology at home and abroad, with high efficiency, energy saving, high starch extraction rate, high ecnomic benefit, practicability and advanced features.

2. Separation section uses the multi-stage filtration, multiple squeeze in circulation process have overcame the pure elutriation filter without drain, starch can not be completely extracted defects, greatly improving the starch extraction yield and extraction rate can reach more than 90%.

3. High starch extraction rate, this potato starch processing line adopt three-stage extruded, multi-stage filtration technology, effectively improve the starch extraction rate.

Potato starch processing equipment

4. Final starch with high quality. It combines fresh potato crhshing, slurry separation, starch filter, and fine filter process as a whole, automatic continuous production, to avoid the starch oxidation and change brown in the processing, final starch is white color, no impurity. High grade, good economic benefit.

5. Large energy saving: Adopt our potato starch processing technology, each ton fresh potato consumes about 1.5kw, compared with similar products in the market, the average energy saving is over 30%.

6. Recycle water, save water effectively: The fine filtration water can be used in the secondary extrusion process, and the waste water can be recycled, this is our potato starch processing technology special features, which can effectively save water resources and reduce the cost.

-

Entire chain of automatic fufu flour production line

Entire chain of automatic fufu flour production line

-

Functions and advantages of centrifuge sieve in potato starch purification line

Functions and advantages of centrifuge sieve in potato starch purification line

-

Manufacturing cycle time of Henan Jinrui's tapioca starch purification equipment

Manufacturing cycle time of Henan Jinrui's tapioca starch purification equipment

-

How Rasper Helps Increase the Efficiency and Productivity for Starch Production

How Rasper Helps Increase the Efficiency and Productivity for Starch Production

-

Advantages of Henan Jinrui's Flash Dryer for Cassava Flour and Starch Production

Advantages of Henan Jinrui's Flash Dryer for Cassava Flour and Starch Production

-

How Much Workshop Area is Needed for a Cassava Flour Plant? How to Place the Layout?

How Much Workshop Area is Needed for a Cassava Flour Plant? How to Place the Layout?

-

How to Ensure the Smooth Operation of Starch Processing Equipment?

How to Ensure the Smooth Operation of Starch Processing Equipment?

-

Common bottlenecks and solutions of cassava flour production

Common bottlenecks and solutions of cassava flour production

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others