Tel/WhatsApp

Tel/WhatsApp

Potato starch production plant

The main characteristic of this process: the whole potato starch production plant adopts closed way and spiral flow device,low consumption, high efficiency and good product quality. In the process of starch recovery and purification, no longer use the centrifuge but spiral flow station, so as to avoid the extensive use of the moving parts.

Potato & potato starch

Potato & potato starch

The whole process in potato starch production plant can be divided into the following units:

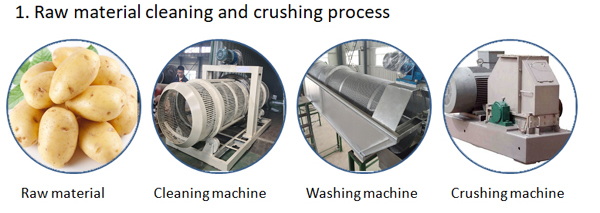

1 Potato Washing/De-stone Unit

New harvest potatoes from the ground should firstly be dried and sieved to remove the impurities as much as possible, and then stored in daily designated area in potato starch production plant.

2 Crushing Unit

Potatoes are fed into rasping machine through screw conveyer. In order to prevent the production line in potato starch production plant from stop when changing the saw blade, it should install the second rasping machine.

Potato cleaning and crushing process

Potato cleaning and crushing process

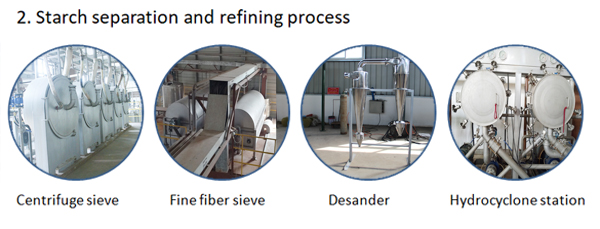

3 Starch separation Unit

The potato slurry after breaking mixed with water then pump into the first level centrifuge sieve in potato starch production plant, and the wet fiber comes down from the first screen is pumped into the second, third and the fourth separation screen, and then be sent to the fine fiber sieve for further separation.

4 Desanding Unit

Starch milk after concentration is sent to a mixing tank in potato starch production plant. The starch can use two levels of de-sander expel sand, and the sand collected uses butterfly valve to eject.

Potato starch production process

Potato starch production process

5 Concentration and refining Unit

Down from desanding process in the potato starch production plant, the starch slurry is pumped into the first level of hydrocyclone station for concentration process. Then starch slurry is concentrated. Then the starches enters into 12-14 level cyclone station to wash, refine and recycle starch slurry. Refining unit automatic work and is equipped with the necessary instruments. Starch slurry concentration after concentration and refining is 35-40%.

6 Dehydration Unit

Starch slurry in starch jar after refined, and then removes moisture through vacuum filter. The wet starch water content after dehydration is 38-40% in potato starch production plant.

Potato starch production process

Potato starch production process

7 Starch drying and sieving Unit

The product after drying uses high efficiency cyclone to collect in potato starch production plant. The finished products of drying machine use pneumatic conveyor or screw conveyor to cool, and then the cooling dry starch will use two stage cyclone separator collection and screw conveyor sends to the sieving machine. After sieving, the finished starch is packed for warehousing. The whole potato starch production plant is completed.

The standard of finished starch in potato starch production plant:

| Water | ≤ 18 ~ 20% |

| Fineness |

≥ 99.6 (100 mesh pass) |

| Protein | ≤ 0.1% |

| Whiteness | ≥ 90% (475mn, reflectivity) |

| Chemical SO2 | ≤ 30ppm |

| Ash | ≤ 0.25 |

| The spots are | ≤3. (fully in line with national first-class standards) |

Water consumption: 2~3T per ton of fresh potato

Power consumption: about 200 degrees per ton of finished product

Coal consumption: about 2 tons of steam per ton of finished product