Tel/WhatsApp

Tel/WhatsApp

Sweet potato starch processing plant

Sweet potato starch production process is composed of raw material preprocessing, starch extraction, starch separation and refining as well as starch dewatering and drying four main section. The main machine used in sweet potato starch processing plant includes dry sieve for cleaning, paddle washing machine, rasper for grinding, centrifuge sieve and fine fiber sieve for separating, hydrocyclone station for refining, vacuum filter for dewatering and flash dryer for drying.

Sweet potato starch processing plant

Sweet potato starch processing plant

1.Raw material preprocessing unit

Functions: In sweet potato starch processing plant, the sweet potato is firstly transported into storage yard for processing. The cleaning and washing unit mainly to clean sweet potato outer epidermis stained with mud, and wash to remove sweet potato root epidermis.

Machines: Dry sieve is and rotary washing machine are used for cleaning and washing in sweet potato starch processing plant. The structure of DOING rotary washing machine is horizontal cylinder, with coarse washing area (including the drainage hole), bathing area, net washing area (including the drainage hole), spray nozzle, rifle, stirring rod, etc. It depends on the motor drive gear rotating cylinder, with water as medium spraying, washing, plunge grinding to remove sediment and sweet potato skins.

Requirements: To remove sediment of sweet potato and peeling rate is above 80%.

Sweet potato starch production process

Sweet potato starch production process

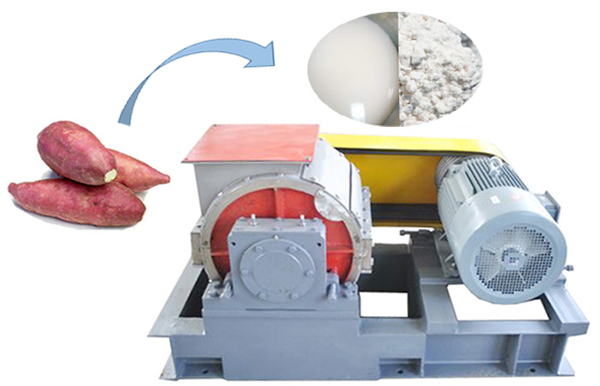

2.Starch extraction unit

Function: The main function of this unit is to grind sweet potato into slurry so that the free starch is released from sweet potato cell. The extraction rate of rasper determines the starch yield.

Machine: DOING rasper is a high efficient grinding machine in sweet potato starch processing plant, its structure composed by the machine cover, enclosure, frame, main shaft, sieve plate, electric motor and so on. It features with high speed, high grinding coefficient machine, compact structure, stable running, easy to install and maintenance.

Requirement: the starch extraction rate is above 94%.

Sweet potato starch grinding machine

Sweet potato starch grinding machine

3. Separating and refining unit

Functions: Sweet potato residue is slender fiber, whose volume is larger than the starch granules, the proportion is lighter than the starch granules. The broken starch, with water as the medium, mixing evenly, is pumped evenly into separating equipment (including centrifuge sieve, fine fiber sieve) where the starch is separeted fibers. In sweet potato starch processing plant, the protein, fine fibers and cell sap are separated by 14-stage hydrocyclone station.

Machines: Centrifuge sieve and fine fiber sieve is are the mainly used separating machine in sweet potato starch processing plant which takes use of centrifugal force to remove starch and fibers. Hydrocyclone station is widely used for refining. The whole hydrocyclone technology includes the concentration, refining, washing and recycling of starch.

Sweet potato starch separating and refining unit

Sweet potato starch separating and refining unit

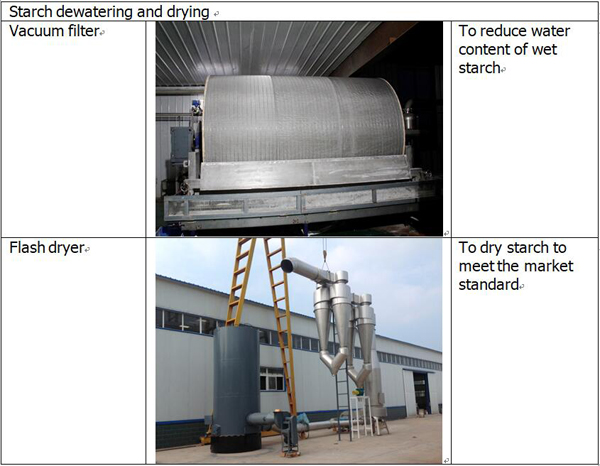

4. Dewatering and drying unit

Function: Wet starch need to be dewatered first to meet the required water content for drying. Then the dewatered starch is dried in flash dryer to meet the marketing standard.

Machines: The sweet potato starch processing plant usually uses vacuum filter for dewatering and flash dryer for frying. This two machine can achieve automatic and continuous operation. The whole process of drying is done in a flash, so the internal moisture has been dry before pasting which prevent the pasting or degradation phenomenon from occuring.

Requirements: The water content of starch after dewatering is about 38%. And the dried starch contains about 13.5% water content in sweet potato starch processing plant.

Sweet potato starch dewatering and drying

Sweet potato starch dewatering and drying

The product after drying uses high efficiency cyclone to collect, finished products use pneumatic conveyor or screw conveyor to cool. Then the sweet potato starch is packed for warehousing. Then the whole process in sweet potato starch processing plant is completed.

This article introduce the main steps in sweet potato starch processing plant and its functions, machines as well as requirements. As a professional starch processing machine manufacturer, we can provide you with a feasibility program about Sweet potato starch processing plant according to your demand and budgets.