Tel/WhatsApp

Tel/WhatsApp

How do you make glucose syrup?

Protein and glucose syrup

How to make glucose syrup

Glucose syrup is a food syrup, made from starch that has been broken down by enzymes and modified. Glucose is the primary end product (~20%) and where it receives its name. Old fashioned corn syrup is just one type glucose syrup. Many of the sugars in this mix are significantly less sweet than sucrose or fructose, so glucose syrup is often used when a less product is desired. It's also least prone to crystallization, and often used in candies. Here we mainly introduce how to make glucose syrup from raw grain corn/corn powder/ rice/ rice powder.

How do you make glucose syrup?

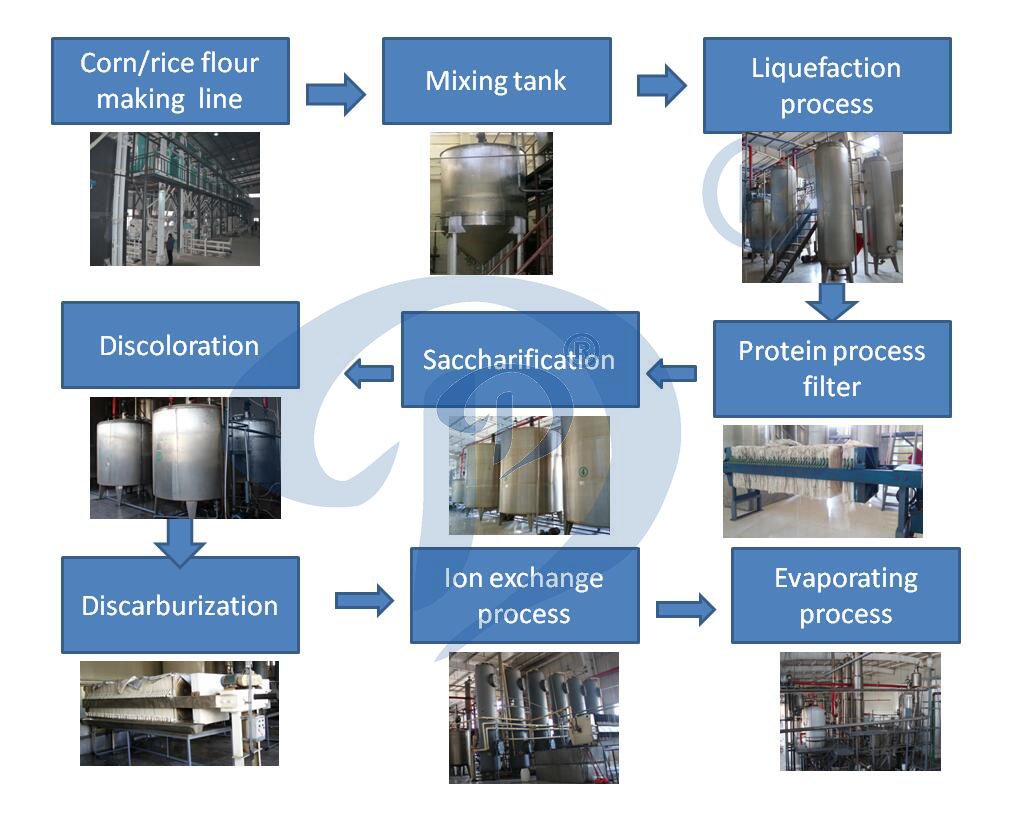

To make glucose syrup,our technology is using corn or rice as raw material direclty,and firstly to process the raw material into flour,(rice flour or corn flour)

2. mixing the flour with water and enzyme with high pressure & high temperature, then it will turn into liquid

3. seperating the protein from the liquid, the protein can be added into animal food, with 38-42% high protein

4. with certain enzyme, temperature pressure, the liquid will into sacchrification

5. putting centain active carbon the make the liquid clear color.

6. with some acid and alkali,to remove the active carbon

7. evaporating the liquid into the requirement desity

During the whole process of glucose making, the most important is our technology, that means the formula, temnperature, pressure's control etc.

-

Investing in Cassava Starch Processing? Start with the Key Equipment for Success in Vietnam/Thailand Markets

Investing in Cassava Starch Processing? Start with the Key Equipment for Success in Vietnam/Thailand Markets

-

The Potato Starch Processing Opportunity in 2025: Benefits and Challenges

The Potato Starch Processing Opportunity in 2025: Benefits and Challenges

-

How to Choose Cassava Starch Processing Machine with Limited Capital to Cater for Both Farmers and Market?

How to Choose Cassava Starch Processing Machine with Limited Capital to Cater for Both Farmers and Market?

-

Sustainable & Eco-Friendly Cassava Processing Solutions

Sustainable & Eco-Friendly Cassava Processing Solutions

-

Solving 5 Common Challenges in Garri Processing with Modern Machinery

Solving 5 Common Challenges in Garri Processing with Modern Machinery

-

Advantages of Cassava Starch Separating Machine - Centrifuge Sieve

Advantages of Cassava Starch Separating Machine - Centrifuge Sieve

-

What is the capacity of cassava slicer manufactured by Henan Jinrui?

What is the capacity of cassava slicer manufactured by Henan Jinrui?

-

How Much is the Cassava Agro Processing Machine Used for Cassava Flour Production?

How Much is the Cassava Agro Processing Machine Used for Cassava Flour Production?

-

Which state in Nigeria produce the most cassava?

Which state in Nigeria produce the most cassava?

-

Ghana kokonte flour processing facility layout and prices

Ghana kokonte flour processing facility layout and prices

-

Henan Jinrui delivers attieke processing equipment to the customer in Côte d'Ivoire

Henan Jinrui delivers attieke processing equipment to the customer in Côte d'Ivoire

-

Henan Jinrui Successfully Ships Cassava Flour Processing Line to Madagascar Client

Henan Jinrui Successfully Ships Cassava Flour Processing Line to Madagascar Client

-

Henan Jinrui Advanced Cassava Starch Processing Equipment Wins Over Nigerian Food Processor

Henan Jinrui Advanced Cassava Starch Processing Equipment Wins Over Nigerian Food Processor

-

Henan Jinrui Delivers Custom 1TPD Garri & Attieke Making Equipment to Benin

Henan Jinrui Delivers Custom 1TPD Garri & Attieke Making Equipment to Benin

-

Henan Jinrui Secures Order from Benin for 1-Ton Daily Garri and Attieke Processing Machines

Henan Jinrui Secures Order from Benin for 1-Ton Daily Garri and Attieke Processing Machines

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others