Tel/WhatsApp

Tel/WhatsApp

Cassava to garri processing machine

- Introduction

Brief introduction of cassava and garri

Garri is a paste-like pellet obtained by processing freshly harvested cassava tubers. It is a staple food in many countries and regions in Africa, such as Nigeria, Ghana, Cameroon, Liberia, Sierra Leon, Benin, etc.

Generally speaking, the yield ratio of cassava and garri is 4:1, but the final garri yield ratio is influenced by many factors, for example, cassava quality, processing technology and garri processing equipment quality.

What machines are needed to process cassava to garri and what are their functions?

In order to increase the value of cassava, many people choose to invest in cassava to garri processing plant and buy processing machine to obtain more benefits. Below I will describe the main cassava to garri processing machine and their functions in detail to help new investors learn more about machines.

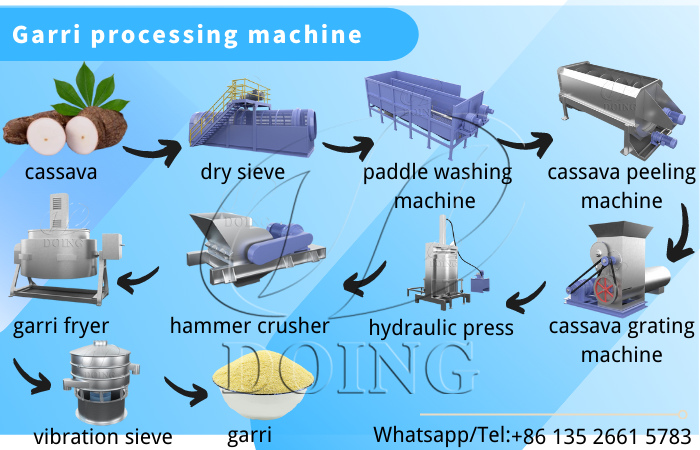

Cassava process flow

Cassava process flow

The needed machines to process cassava to garri and their functions are as follows:

1.Dry sieve: used to remove dirt, sand, weeds, small stones and other impurities on the surface of cassava.

2.Paddle washing machine: used to wash cassava completely and eliminate sand & mud effectively.

3.Cassava peeling machine: used to remove two layers of cassava tuber.

4.Cassava grinding machine: used to crush fresh cassava tubers into cassava mash.

5.Dewatering machine/Hydraulic press: used to squeeze out the water in the crushed cassava by virtue of hydraulic principle.

6.Hammer crusher: used to mill the cassava cake into small cassava powdery particles.

7.Garri fryer: used to stir and fry garri automatically.

8.Vibration sieve: used to screen garri with different size particles.

Processing capacity of cassava to garri processing machine

The common processing capacity of cassava to garri processing machine is 500kg to 20 tons per day or more. If you have machine purchase requirements, you can contact professional and reliable machine manufacturer to customize the most suitable cassava to garri processing machine at the same time saving investment cost.

Garri processing flow

Garri processing flow

Why choose Jinrui’s cassava to garri processing machine?

1.Jinrui’s cassava to garri processing machine has the advantages of mature processing technology, high automatic degree, stable operation, easy handling and maintenance, low power consumption, small footprint, etc. Our cassava to garri processing machine is hot sale in more than 30 countries and regions.

2.Jinrui has 10+ years cassava to garri processing machine manufacturing and installing experience. And we have developed our own factory and professional engineer team, include process engineer, mechanical engineer, electrical engineer, installation team, etc.

3.Jinrui can provide excellent after-sales service and all-round technical support, like factory visiting, machine installation and debugging, worker training service, etc. All our machines have one year warranty. And once there is any problem on machine running, we can provide online or video guide any time.

Suggestion to You from DOING - Henan Jinrui Company

Cassava has a period of freshness, it’s suggested to finish cassava to garri processing in one weeks after the cassava harvest time. If you have any ideas about investing in cassava to garri processing business, welcome to consult us and we can help you obtain more benefits!

-

Why sand roller cassava peeling machine is more suitable for cassava processing?

Why sand roller cassava peeling machine is more suitable for cassava processing?

-

How Many Types of Cassava Peeler Are Available on the Market & How to Choose?

How Many Types of Cassava Peeler Are Available on the Market & How to Choose?

-

How to Choose a Reliable Bammy Making Plant? Key Factors List

How to Choose a Reliable Bammy Making Plant? Key Factors List

-

How to Produce International Standard Cassava Starch?

How to Produce International Standard Cassava Starch?

-

Move Beyond Local Cassava Pressing Machines with Henan Jinrui Reliable Equipment

Move Beyond Local Cassava Pressing Machines with Henan Jinrui Reliable Equipment

-

Garri Processing vs. Cassava Starch Processing: Which is More Profitable and Easier to Start?

Garri Processing vs. Cassava Starch Processing: Which is More Profitable and Easier to Start?

-

Investing in Cassava Starch Processing? Start with the Key Equipment for Success in Vietnam/Thailand Markets

Investing in Cassava Starch Processing? Start with the Key Equipment for Success in Vietnam/Thailand Markets

-

The Potato Starch Processing Opportunity in 2025: Benefits and Challenges

The Potato Starch Processing Opportunity in 2025: Benefits and Challenges

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others