Tel/WhatsApp

Tel/WhatsApp

2024 latest fully automatic Garri processing line

- Introduction

Good news! As a manufacturer in the cassava processing industry, based on its many years of experience, Jinrui Company updated its garri processing technology this year.

This fully automatic Garri processing line is designed to increase efficiency, reduce labor costs, and ensure consistent product quality. In the new Garri processing line, we use a new way of filling fermenters and a new way of dewatering for true automation.

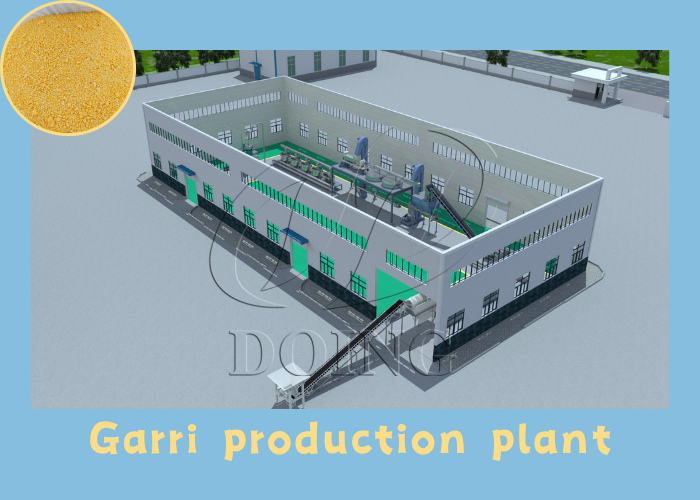

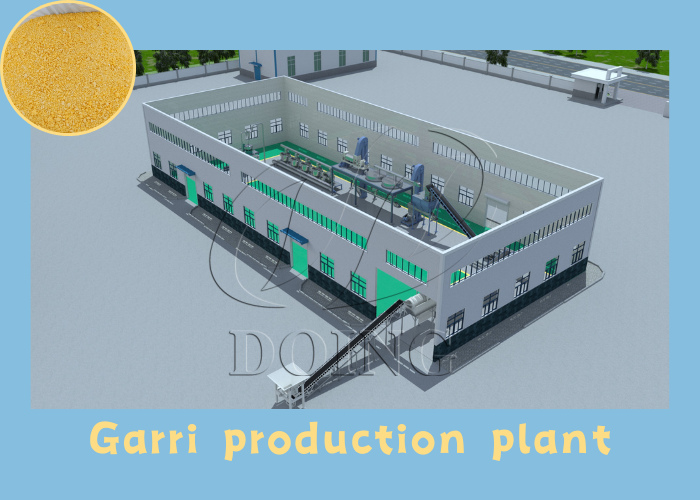

Garri processing line

Garri processing line

The revised Garri processing line involves the use of a dry sieve, paddle washer, peeling machine, fermentation tank, spiral press, Garri fryer, air-cooling system, and packaging machine.

It includes several advances.

1. The latest Garri processing line is capable of handling large volumes of cassava with increased speed and accuracy, allowing for faster production cycles.

2. From peeling and washing the cassava to grating, frying, and packaging, the entire process is automated, minimizing manual intervention and reducing the risk of contamination.

3. This line incorporates energy-saving technologies to reduce electricity and fuel consumption, contributing to sustainable production practices.

4. Adopt Advanced control systems to enable precise monitoring and adjustment of process parameters such as temperature, time, and moisture content, ensuring optimal processing conditions for high-quality garri.

5. Designed for easy access and maintenance, this Garri processing line facilitates regular cleaning and maintenance schedules to maintain hygiene and equipment longevity.

6. Safety measures are integrated throughout the Garri processing line to protect operators and prevent accidents, including emergency stop buttons, guards, and alarms.

7. Real-time data monitoring and reporting capabilities allow for tracking production performance, identifying potential issues, and optimizing processes for continuous improvement.

We manufacture the 2024 latest fully automatic Garri processing line to offer a range of customization solutions to meet specific production needs and requirements. When you select a cassava processing line, it is essential to consider factors such as production capacity, budget, available space, and future scalability. If you are interested, welcome to contact us

PREV:Nothing

PREV:Nothing

-

How to Produce International Standard Cassava Starch?

How to Produce International Standard Cassava Starch?

-

Move Beyond Local Cassava Pressing Machines with Henan Jinrui Reliable Equipment

Move Beyond Local Cassava Pressing Machines with Henan Jinrui Reliable Equipment

-

Garri Processing vs. Cassava Starch Processing: Which is More Profitable and Easier to Start?

Garri Processing vs. Cassava Starch Processing: Which is More Profitable and Easier to Start?

-

Investing in Cassava Starch Processing? Start with the Key Equipment for Success in Vietnam/Thailand Markets

Investing in Cassava Starch Processing? Start with the Key Equipment for Success in Vietnam/Thailand Markets

-

The Potato Starch Processing Opportunity in 2025: Benefits and Challenges

The Potato Starch Processing Opportunity in 2025: Benefits and Challenges

-

How to Choose Cassava Starch Processing Machine with Limited Capital to Cater for Both Farmers and Market?

How to Choose Cassava Starch Processing Machine with Limited Capital to Cater for Both Farmers and Market?

-

Sustainable & Eco-Friendly Cassava Processing Solutions

Sustainable & Eco-Friendly Cassava Processing Solutions

-

Solving 5 Common Challenges in Garri Processing with Modern Machinery

Solving 5 Common Challenges in Garri Processing with Modern Machinery

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others