Tel/WhatsApp

Tel/WhatsApp

FOCUS ON CASSAVA MANUFACTURING PROCESS

DOING delivers the whole range of equipment for the cassava processing industry from single machines to complete cassava-processing plants

BUSINESS SCOPE

Cassava Starch, Cassava Flour, Garri, Potato starch, Sweet potato starch processing machine

TURNKEY BUSINESS SOLUTION

We can provide you with all the solutions from production line design to smooth production

PRODUCTION LINE AND

SINGLE MACHINE OF STARCH, FLOUR AND GARRI PROCESSING

- cassava starch processing machine

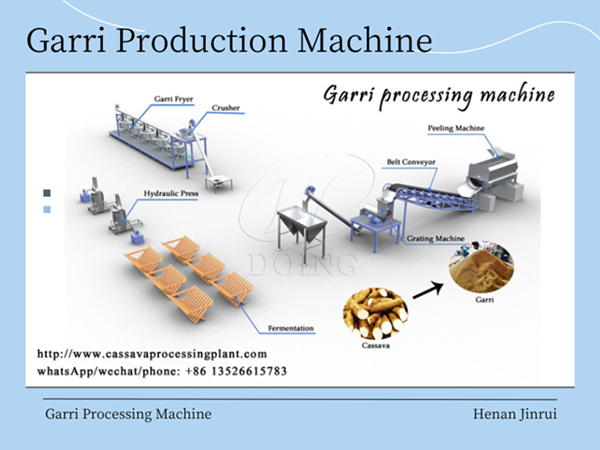

- garri processing machine

- potato starch processing machine

- sweet potato starch processing machine

- cassava flour processing machine

Cassava fiber separating machine

— Centrifuge sieve

Centrifugal sieve is mainly used to screen the raw material pulp after crushing so as to separate the starch. The part of the centrifugal sieve that contacts the starch is made of stainless steel, the surface of the machine is made of unique processing technology, and the screen is made of titanium steel plate.

Cassava cutting machine

— Cassava cutter

The cassava cutting machine is used for pre-crushing of raw materials. It cuts raw materials into small pieces to facilitate subsequent processing. Cassava cutting machine consist of foundation, main frame, blades, motor and drive system. The blade is specially designed, durable and easy to disassemble and maintain.

Cassava grinding machine

— Rasper machine

The rasper machine is an ideal machine for grinding raw materials into slurry. This machine is mainly composed of shell, rotor device, saw blade, base mesh, engine, etc. The grinding block of the machine adopts modular design, and the part in contact with the material is made of stainless steel.

Starch drying machine

— Flash dryer

The flash dryer is suitable for drying all kinds of starch and powder. It adopts negative pressure drying system, and strictly controls the technical parameters of each part on the basis of theoretical calculations to ensure the physical and chemical indicators of the dried materials.

Starch refining machine

— Hydrocyclone

The hydrocyclone is used to remove the fine fiber, protein and cell fluid in starch milk. It can concentrate and purify starch milk. The general process of complete hydrocyclone includes three parts: concentration, recovery and refinement. The hydrocyclone not only has good separation effect, but also has low energy consumption.

THE VIDEO

OF SUCCESSFUL PROJECTS AND MACHINE OPERATION

-

How Does a Modern Cassava Cleaning Plant Work? See It in Action

This video provides a detailed look inside the operation of a high-capacity cassava cleaning plant. You will see the mechanical agitation of this cassava cleaning machine effectively separates mud, stones, sand, and light impurities from the cassava skin.

-

Henan Jinrui Automatic Cassava Flour Dewatering Machine in Operation

Look! The cassava flour dewatering machine manufactured by Henan Jinrui is operating in the factory. It achieves excellent dewatering results by applying immense pressure, and features automatic feeding and unloading for fully automated production!

-

Fufu Flour Processing Line Work Process 3D Video

This 3D video shows the work process and equipment configuration of fufu processing line, in which you will see the three processing parts and relevant machines.

-

Cassava Manioc Peeling Machine Operation Video

The video shows the operation of cassava manioc peeling machine which has better peeling effect as well as reducing starch loss, widely used in different cassava products processing lines, such as garri, fufu, cassava flour, attieke, etc.

FREQUENTLY ASKED QUESTIONS

THAT SOME QUESTIONS YOU MAY BE INTERESTED IN OR WANT TO KNOW

What is the best cassava starch extraction method?

Different cassava starch extraction methods are suitable for producers with diff...

What are the advantages of the fully automatic electric cassava Garri fryer machine?

The Garri fryer of Henan Doing Company overcomes the backwardness and limitation...

-

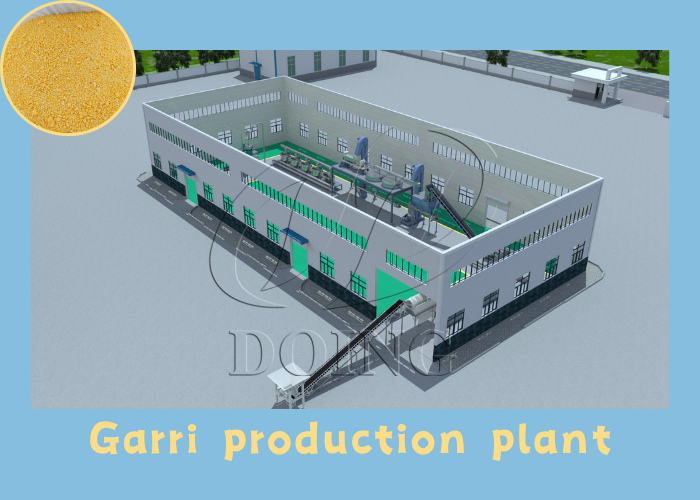

Equipment Design in a Garri Processing Factory

-

Why sand roller cassava peeling machine is more suitable for cassava processing?

-

How Many Types of Cassava Peeler Are Available on the Market & How to Choose?

-

How to Choose a Reliable Bammy Making Plant? Key Factors List

-

How to Produce International Standard Cassava Starch?

-

Move Beyond Local Cassava Pressing Machines with Henan Jinrui Reliable Equipment

-

Garri Processing vs. Cassava Starch Processing: Which is More Profitable and Easier to Start?

OUR ADVANTAGES

WHAT MAKES US DIFFERENT

Professional team

Over 10 years’ experience in cassava processing industry and installed many cassava processing machines at home and abroad.

Perfect service

Not only provide you with high-quality cassava processing machine, but also provide you with 24/7/365 lifetime technical support.

Quality assurance

Each batch of cassava processing machine undergoes strict quality control and operational testing before shipment.

Overseas warehouse

In order to facilitate customers to take delivery of goods, our company has an overseas warehouse in Nigeria.

SUCCESSFUL PROJECTS

OF STARCH, FLOUR AND GARRI PROCESSING PLANT

Heilongjiang

Heilongjiang

The 2tph potato starch processing plant project was installed and operated in Heilongjiang!

In September 2022, a complete set of 2tph potato starch processing plant project was successfully installed and operated in Heilongjiang. This machine can make fresh potatoes into ...

Congo

Congo

8TPH cassava/fufu flour processing plant project installed in Congo

In July 2022, one set cassava/fufu flour processing plant project in Congo was successfully installed and put into production. This cassava/fufu flour processing plant is mainly us...

Liberia

Liberia

1TPH garri production machine project in Liberia

At the end of 2018, the professional engineer team of Henan Jinrui Company helped the Liberia client install 1TPH garri production machine. Now the client has successfully put into...

LATEST NEWS

ABOUT OUR COMPANY AND WHOLE INDUSTRY

- Enterprise news

- Industry news

-

12

2025 December

Henan Jinrui delivers attieke processing equipment to the customer in Côte d'Ivoire

On November 14, Henan Jinrui delivered an Attieke processing line to a customer in Côte d'Ivoire at DOING factory. The line includes a cassava peeler, grinder, dehydration equipment, granulation equi...

-

1

2025 December

Henan Jinrui Successfully Ships Cassava Flour Processing Line to Madagascar Client

On November 17, a complete cassava flour processing line supplied by Henan Jinrui Company was successfully shipped from the Doing factory to Madagascar, including washing, grinding, dehydration, dryin...

-

12

2025 November

Henan Jinrui Advanced Cassava Starch Processing Equipment Wins Over Nigerian Food Processor

With its comprehensive advantages, including professional services, advanced equipment, and localized layout, Henan Jinrui successfully secured a starch equipment order from a Nigerian cassava process...

-

5

2025 November

Henan Jinrui Delivers Custom 1TPD Garri & Attieke Making Equipment to Benin

Henan Jinrui shipped a 1TPD garri & attieke making equipment to Benin on Oct 15, 2025. This integrated cassava processing line enhances local production capacity with high-efficiency equipment.

-

9

2025 July

Garri Processing Equipment: A Deep Dive into Production Costs and Profitability

It's important to learn about the production cost and profitability of garri processing equipment before entering garri processing industry. Making full preparation for your garri processing project a...

-

29

2024 May

Cassava transformation into gari granules facility shipped to Guyana

On May 31st, 2024, cassava transformation into gari granules facility was shipped to Guyana from Henan Jinrui’s cassava machinery manufacturing factory.

-

10

2024 January

15tph full set cassava chips processing facility was shipped to Laos

On January 7th,2024, 15tph full set cassava chips processing facility was shipped to Laos from Henan Jinrui. This whole set of cassava chips processing facility include a feeding hopper, a dry sieve a...

-

28

2023 December

Cassava mill and garri sieving plant designed for standardized garri production was dispatched to Nigeria

On December 26th, the cassava mill and garri sieving plant designed for standardized garri production was dispatched from Henan Jinrui to Nigeria. The entire transportation process is expected to last...

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others