Tel/WhatsApp

Tel/WhatsApp

FREQUENTLY ASKED QUESTIONS

THAT SOME QUESTIONS YOU MAY BE INTERESTED IN OR WANT TO KNOW

Q:How to ferment fufu?

A:

Fermenting fufu can involve both pre-crushing fermentation and post-crushing fermentation in a fermentation tank. Here's an overview of both processes, along with a comparison of time and cost....

Q:How does the starch rasping machine enhance starch yield?

A:

The starch rasping machine plays a crucial role in the starch extraction process from various starchy materials, particularly cassava roots.The enhanced starch yield can be attributed to several factors like efficient grinding and separation, reduced loss...

Q:Small and large scale cassava flour production lines

A:

Cassava flour production lines can vary greatly in scale, from small-scale operations suitable for small businesses or startups to large-scale industrial operations. Below are general outlines for both small and large scale cassava flour production lines....

Q:Cassava peeling machine costs and working principle

A:

A cassava peeling machine is essential for efficiently removing the outer skin from cassava tubers, facilitating their use in food production, animal feed, or biofuel. Here's an overview of costs and working principle of cassava peeling machine....

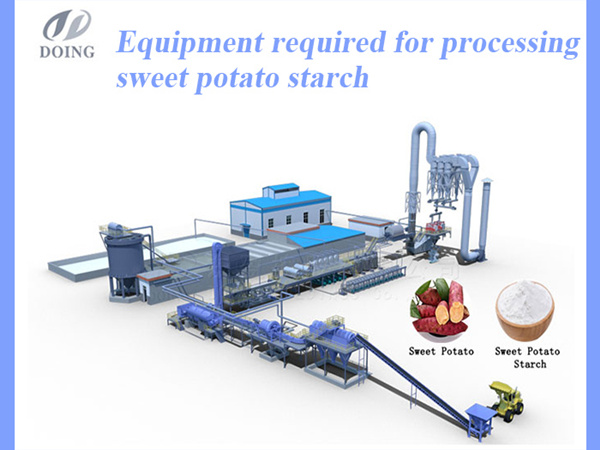

Q:How to process sweet potato into starch by sweet potato starch production machine?

A:

The sweet potato starch production process includes several steps: sweet potato cleaning and washing, sweet potato milling, sweet potato starch extraction, starch milk refining, starch dewatering, and drying....

Q:How to process cassava flour by dry method?

A:

Processing cassava flour by dry method is a traditional approach that involves several key steps. This method contrasts with wet processing and has its own set of advantages and disadvantages. Now we will introduce how to process cassava flour by dry met...

Q:Whole set Attieke Machine For Production Efficiency

A:

Henan Jinrui can provide an attieke machine from cassava input to the dewatering process. The attieke machines include dry sieve, paddle washing machine, peeler, grinder, and hydraulic press for production efficiency....

Q:Cassava transformation into garri procedure

A:

Cassava can help make large profits through further transformation into cassava destrives. Main cassava products sold well in the international market include cassava flour, cassava starch, and garri etc. In this article, we will introduce you the procedu...

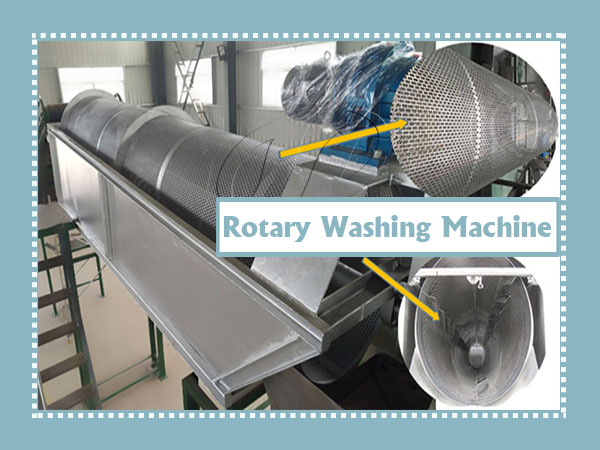

Q:Rotary washing machine

A:

In potato/sweet potato starch processing, a washing machine is necessary before next step. In the market, there are different washing machines for sale, this article will introduce you the rotary washing machine for starch production....

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others