Tel/WhatsApp

Tel/WhatsApp

How does the starch rasping machine enhance starch yield?

The starch rasping machine plays a crucial role in the starch extraction process from various starchy materials, particularly cassava roots. Its design and operational mechanisms significantly enhance starch yield, contributing to more efficient and profitable production. How does the starch rasping machine enhance starch yield? It can be attributed to several factors, including efficient grinding and separation, reduced losses, increased processing capacity, and consistent product quality.

starch rasper

starch rasper

Efficient Grinding and Separation

At the heart of the starch extraction process is the grinding and separation mechanism. The starch rasping machine is specifically engineered to efficiently grind cassava roots or other starch-rich materials into a fine pulp. This grinding process is essential because it breaks down the cellular structure of the raw materials. By doing so, it releases a greater number of starch granules into the pulp.

Henan jinrui's starch rasper

Henan jinrui's starch rasper

When the cassava is processed using traditional methods, the grinding is often incomplete, leaving significant quantities of starch trapped within the fibrous material. The rasping machine, however, employs advanced grinding techniques that ensure a more thorough breakdown, allowing for maximum starch extraction.

Once the grinding is completed, the subsequent stages of starch recovery—such as centrifugation or sieving—become much more effective. The finely ground pulp facilitates the easy isolation of starch granules from the remaining fibrous material. As a result, the overall starch yield is significantly increased. The improved grinding and separation capabilities of the starch rasping machine ensure that more starch is recovered from each batch of raw material.

Reduced Losses

Traditional methods of starch extraction often involve a series of manual processes that can result in significant losses. These losses may occur due to spillage, contamination, or incomplete extraction of starch from the raw materials. The starch rasping machine automates many of these processes, thereby minimizing losses that are typically associated with manual handling.

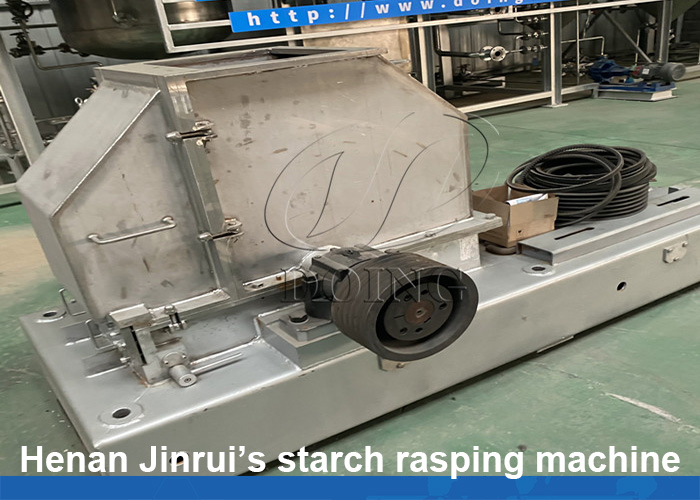

Starch rasping machine in henan jinrui's factory

Starch rasping machine in henan jinrui's factory

For instance, the automation of grinding reduces the likelihood of spillage, as the machine processes the material in a controlled environment. Additionally, the risk of contamination is lower when using machinery compared to manual methods, where human error can introduce foreign materials into the starch product.

Furthermore, the efficient design of the rasping machine ensures that almost all of the starch granules are extracted from the pulp. This means that even the smallest quantities of starch, which might otherwise be lost in traditional methods, are captured and processed. By significantly reducing losses, the starch rasping machine contributes to an overall increase in starch yield, making the extraction process much more efficient.

Increased Capacity

Another significant advantage of the starch rasping machine is its increased processing capacity compared to manual or semi-automated methods. The machine is designed to handle larger quantities of raw materials in a shorter time frame. This high capacity is vital for commercial starch production, where demand for starch can be substantial.

Henan Jinrui's engineers are manufacturing starch rasper

Henan Jinrui's engineers are manufacturing starch rasper

With the ability to process more material at once, the starch rasping machine allows manufacturers to scale up their operations. This scalability translates to increased production volumes and, consequently, higher overall starch yields. In environments where time is of the essence, the ability to quickly and efficiently process large batches of raw material can be a game-changer.

Moreover, the higher capacity of the starch rasping machine reduces the need for multiple processing runs. This not only saves time but also optimizes resource utilization. Energy consumption and labor costs are significantly lowered, making the starch extraction process more cost-effective.

Consistent Quality

Quality consistency is another critical factor that contributes to the effectiveness of starch production. The starch rasping machine ensures uniform processing conditions throughout its operation. This consistency in processing results in a higher quality starch product, which is essential for market acceptance.

Details of starch rasper

Details of starch rasper

When starch is produced under uniform conditions, variations in quality are minimized. This uniformity leads to a starch product that meets industry standards and consumer expectations. In turn, a consistent and high-quality product can boost market acceptance and enhance demand for the starch.

Additionally, consistent quality reduces the risk of product rejection from buyers, which can lead to increased sales and profitability. Manufacturers can build a strong reputation for quality, which is invaluable in a competitive market.

In summary, the starch rasping machine significantly enhances starch yield through its efficient grinding and separation processes, reduced losses, increased capacity, and consistent product quality. These factors not only improve the efficiency of starch extraction but also contribute to the overall profitability of starch production operations. By investing in modern starch rasping machines, manufacturers can achieve higher yields, reduce operational costs, and deliver superior products to the market. If you have interest in this starch rasping machine, welcome to contact us!

-

Fufu Production Line Layout in Cassava Processing Plant

Fufu Production Line Layout in Cassava Processing Plant

-

Henan Jinrui Four Types of Dehydration Equipment for Cassava Processing Introduction

Henan Jinrui Four Types of Dehydration Equipment for Cassava Processing Introduction

-

Entire chain of automatic fufu flour production line

Entire chain of automatic fufu flour production line

-

Functions and advantages of centrifuge sieve in potato starch purification line

Functions and advantages of centrifuge sieve in potato starch purification line

-

Manufacturing cycle time of Henan Jinrui's tapioca starch purification equipment

Manufacturing cycle time of Henan Jinrui's tapioca starch purification equipment

-

How Rasper Helps Increase the Efficiency and Productivity for Starch Production

How Rasper Helps Increase the Efficiency and Productivity for Starch Production

-

Advantages of Henan Jinrui's Flash Dryer for Cassava Flour and Starch Production

Advantages of Henan Jinrui's Flash Dryer for Cassava Flour and Starch Production

-

How Much Workshop Area is Needed for a Cassava Flour Plant? How to Place the Layout?

How Much Workshop Area is Needed for a Cassava Flour Plant? How to Place the Layout?

-

How to Ensure the Smooth Operation of Starch Processing Equipment?

How to Ensure the Smooth Operation of Starch Processing Equipment?

-

Common bottlenecks and solutions of cassava flour production

Common bottlenecks and solutions of cassava flour production

-

Garri Processing Equipment: A Deep Dive into Production Costs and Profitability

Garri Processing Equipment: A Deep Dive into Production Costs and Profitability

-

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

-

Selling High-Quality Cassava Processing Equipment to Uganda

Selling High-Quality Cassava Processing Equipment to Uganda

-

Gari processing line successfully shipped to Nigeria

Gari processing line successfully shipped to Nigeria

-

Cassava starch fine fiber sieve purchased by Indian client

Cassava starch fine fiber sieve purchased by Indian client

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others