Tel/WhatsApp

Tel/WhatsApp

FREQUENTLY ASKED QUESTIONS

THAT SOME QUESTIONS YOU MAY BE INTERESTED IN OR WANT TO KNOW

Q:A guide to expanding from cassava planting to cassava flour processing in Indonesia

A:

Indonesia is one of the largest cassava growers in the world. Now more and more locals are beginning to expand from cassava planting to the cassava flour processing industry. Here Henan Jinrui provides you with a comprehensive guide!...

Q:The Advantages of Fully Automatic Potato Starch Production Lines

A:

Fully automatic potato starch production lines have advantages like high yield, enhanced consistency, and superior quality over traditional semi-automatic or manual methods....

Q:From cassava to fufu flour: key processing steps and quality control points

A:

From cassava to fufu flour, it need to undergo cleaning, peeling, grinding, dewatering, fermentation, drying, etc. steps. In this article, Henan Jinrui will introduce the key processing steps and quality control points in fufu flour production....

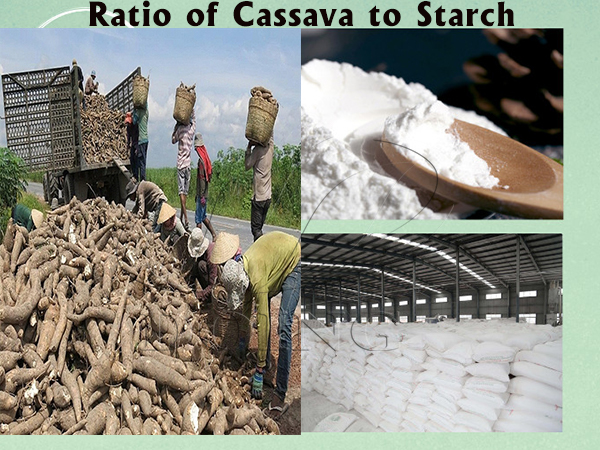

Q:Ratio of cassava to starch: How many tons of cassava can extract one-ton starch?

A:

How many tons of cassava can extract one-ton starch? This question often asked by many cassava starch processors, is related to the profit of cassava starch processing business. Generally speaking, 3.5-4 tons of cassava are needed to produce 1 ton starch....

Q:Market introduction to Polvilho (cassava starch) processing industry in Colombia

A:

Colombia’s Polvilho (cassava starch) processing industry represents a niche yet strategically significant segment within the global starch market. Rooted in traditional practices but increasingly shaped by modern food trends, this sector offers unique opp...

Q:From cassava chips to HQCF(high quality cassava flour): What machines will be used?

A:

The processing machines used to process cassava chips into HQCF(high quality cassava flour) includes milling machine and sieving machine. However, the quality of cassava flour processed in this way is directly affected by the raw material cassava chips....

Q:Scaling Up Thai Tapioca Starch Production: High-Capacity, Automated Processing Lines

A:

Thailand, as the top 5 exporter of tapioca starch, has a large potential to earn money globally. And the automation of cassava starch production line fuels to increase the yield and quality, finally boosting economy....

Q:The Basic Equipment Needed for Wet Method Cassava Flour Commercial Production

A:

The cassava flour processing methods divides into dry method and wet method. This article introduce the basic equipment for wet method cassava flour commercial production, including washing and peeling machine, grinder, dehydrator, drying machine, etc....

Q:Why Cassava Starch Producers Prefer Small Scale Starch Production Systems

A:

The small scale starch production systems are favored by more and more cassava starch producers, because of its flexible scalability, sustainable performance, cost-effectiveness, easy installation and maintenance, etc....

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others