Tel/WhatsApp

Tel/WhatsApp

How to ferment fufu?

Fermenting fufu can involve both pre-crushing fermentation and post-crushing fermentation in a fermentation tank. Here's an overview of both processes, along with a comparison of time and cost, followed by a brief introduction to the fufu production line.

Pre-Crushing Fermentation

1. Process Overview:

In pre-crushing fermentation, the raw materials (usually cassava or similar starchy tubers) are first allowed to undergo a natural fermentation process before being crushed.

The tubers are soaked in water for several days to initiate microbial growth, particularly lactic acid bacteria, which begin breaking down the starches into sugars.

This fermentation step enhances the flavor and digestibility of the fufu.

Fufu flour production line

Fufu flour production line

2. Time Comparison:

Pre-crushing fermentation can take anywhere from 24 hours to several days, depending on the temperature and microbial activity.

It typically adds to the overall production time but can improve the quality of the final product.

3. Cost Comparison:

While it may not significantly reduce the direct material costs, pre-crushing fermentation can lead to better fermentation efficiency and potentially reduce the need for additives or enzymes in the subsequent steps.

Post-Crushing Fermentation Tank Fermentation

1. Process Overview:

After crushing the raw materials, the resulting pulp is transferred to a fermentation tank.

Here, controlled conditions (such as temperature, pH, and agitation) are maintained to optimize microbial growth and fermentation.

The lactic acid bacteria continue to break down starches, producing lactic acid, which gives fufu its characteristic sour taste and texture.

2. Time Comparison:

Post-crushing fermentation in a tank is typically shorter than pre-crushing fermentation, as the process is more controlled and efficient.

Depending on the desired final product, the fermentation time in the tank can range from a few hours to a day or two.

3. Cost Comparison:

The use of a fermentation tank requires initial investment in equipment but can lead to more consistent and efficient fermentation.

It may also reduce labor costs and the need for extensive monitoring during the fermentation process.

Fufu Production Line

The fufu production line typically involves the following steps:

1. Raw Material Preparation: The tubers are cleaned, peeled (if necessary), and sliced or grated.

2. Crushing: The prepared tubers are crushed to form a pulp.

3. Fermentation: Depending on the chosen method, the pulp undergoes either pre-crushing fermentation or is directly transferred to a fermentation tank for post-crushing fermentation.

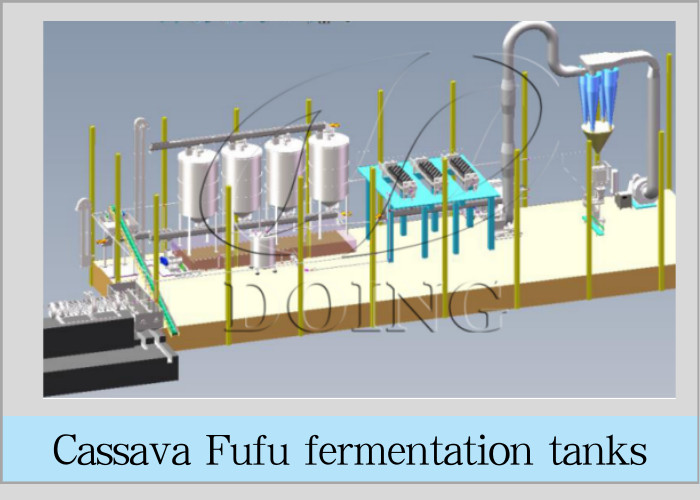

Fufu fermentation tanks

Fufu fermentation tanks

4. Drying: The fermented pulp is dried to remove excess moisture, often using solar drying or mechanical dryers.

5. Packaging: The dried fufu is packaged and labeled for sale.

By incorporating either pre-crushing or post-crushing fermentation into the production line, manufacturers can produce fufu with varying textures, flavors, and nutritional profiles to cater to different consumer preferences.

-

Reasons for excessive impurities in cassava starch production

Reasons for excessive impurities in cassava starch production

-

Main Factors Influencing the Price of Cassava Starch Processing Equipment

Main Factors Influencing the Price of Cassava Starch Processing Equipment

-

Tips for buying fufu making machine

Tips for buying fufu making machine

-

How to transform cassava into cassava slices?

How to transform cassava into cassava slices?

-

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

-

What should I pay attention to for reducing starch loss during cassava starch production?

What should I pay attention to for reducing starch loss during cassava starch production?

-

Common Problems and Solutions During Cassava Starch Production

Common Problems and Solutions During Cassava Starch Production

-

How Does a Cassava Grinder Work?

How Does a Cassava Grinder Work?

-

Advantages of cassava peeler used for cassava agriculture

Advantages of cassava peeler used for cassava agriculture

-

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

-

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

-

Selling High-Quality Cassava Processing Equipment to Uganda

Selling High-Quality Cassava Processing Equipment to Uganda

-

Gari processing line successfully shipped to Nigeria

Gari processing line successfully shipped to Nigeria

-

Cassava starch fine fiber sieve purchased by Indian client

Cassava starch fine fiber sieve purchased by Indian client

-

Gari making plants were transported to Ghana from Henan Jinrui’s factory

Gari making plants were transported to Ghana from Henan Jinrui’s factory

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others