Tel/WhatsApp

Tel/WhatsApp

The potato starch machine plant installed in Inner Mongolia,China

With the season changing in China, It will be the heavest season soon in Autumn. During autumn, Noth of CHina farmer will harvest corn, cotton,potato, sweet potato etc.And soon, the potato starch processing season will coming too.

Potato starch processing machine plant

Two months ago. our customer from Neimenggu Province,China come to visit our factory about the potato starch machine and confirm the whole plant of potato starch machine 30ton per day output.This month, we are arrange shipping of the potato starch machine plant to customer site. and start the installation of potato starch machine soon, which will also be finished in one months.

For our potato starch machine plant, what we used is the Newest European Cyclone technology to extract starch from sweet potato or potato.Which will ensure the final starch with level-A quality.

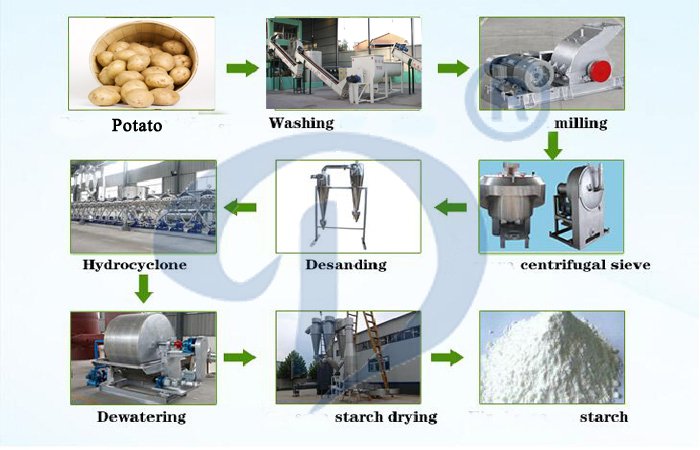

Below is the potato starch processing machine plant description:

(1) Raw material receiving unit: We normaly match a hopper used to reception of potatoes or sweet potatoes.

(2) De-stone and washing unit during the potato starch processing machine plant: Potato is transferred into the screw destone machine to be cleaned by water flow.Cleaned potato falls on a checking conveying belt equipped with nozzles for washing the surface of potato. Workers can manually take out the rotten potatos, wooden and plastic items.

(3) Milling unit: The milling unit is the most important step for extracting potato starch. we can use hammer mill or rasper to mill potatoes and extract starch.

Potato starch processing machine

(4) Centrifugal extracting unit during the potato starch processing machine plant : The mixture is transferred to the 3 stage centrifugal sieves, each sieve works with a fiber pump and a defoam pump. The mixture enters into each sieve to separate residue and starch. After 3 stages continuous washing and separation, the filtrate is sent to concentration and refining unit, and the residue is sent to the residue dewatering unit.

Potato starch processing machine

(5) De-sanding unit during the potato starch processing machine plant: the starch milk is transferred to de-sanding cyclone by fiber pump. The hydro-cyclone divide the milk into two parts: the light part which contains the mixture of starch and residue will go out from top of the cyclone, and the heavy part which contains the sand will be discharged out of the system.

(6) Starch concentration and refining unit during the potato starch processing machine plant: The starch milk goes into the 18 stages of refining hydro-cyclone, and fresh water comes into the cyclone from the end of system. Firstly, starch milk is pumped into 3 stages of concentration unit to remove the water, then the condensed starch milk enter the next 13 stages of washing unit, and the overflow enters into another 2 stages of recycle unit to recycle starch. Most of the effluent with fiber is discharged out of the process, and a little part goes back to the process water system. Finally, the condensed starch slurry is pumped into the starch slurry storage tank.

Vacuum dewatering machine

(7) Vacuum dewatering unit during the potato starch processing machine plant : The starch slurry is pumped into inlet tank of vacuum dewatering machine. Then the vacuum rotary drum will adsorb the starch on the drum surface and the filtrate is transferred out of the system by filtrate pump. The filter cake on the drum will be peeled off by peeler and then transferred to the air dryer by screw conveyor.

(8) Air drying unit: After dewatering process, the air dryer will dry the starch to the required moisture of the commercial starch. Our dryer is professional for starch dryer, which can dry starch in 45℃, ensure the good quality of potato starch.

(9) Packaging unit: Pack the potato starch into required weight and storage it.

Potato starch processing plant

We can provide you the complete set potato starch processing plant and the other starch processing machine.The raw material of starch processing plant can be cassava,potato,sweet potato and other grain.

-

The 2tph potato starch processing plant project was installed and operated in Heilongjiang!

The 2tph potato starch processing plant project was installed and operated in Heilongjiang!

-

8TPH cassava/fufu flour processing plant project installed in Congo

8TPH cassava/fufu flour processing plant project installed in Congo

-

1TPH garri production machine project in Liberia

1TPH garri production machine project in Liberia

-

20TPH tapioca starch processing plant installed in Indonesia

20TPH tapioca starch processing plant installed in Indonesia

-

DOING potato starch processing plant installed in India

DOING potato starch processing plant installed in India

-

DOING second time install cassava processing factory in Nigeria!

DOING second time install cassava processing factory in Nigeria!

-

Tanzania cassava flour processing factory turnkey project

Tanzania cassava flour processing factory turnkey project

-

Jiaozuo 25TPH processing capacity potato starch processing plant

Jiaozuo 25TPH processing capacity potato starch processing plant

-

Potato starch drying machine delivery to Ukraine client

Potato starch drying machine delivery to Ukraine client

-

Cassava starch production plant installed in Cambodia

Cassava starch production plant installed in Cambodia

-

Henan Jinrui delivers attieke processing equipment to the customer in Côte d'Ivoire

Henan Jinrui delivers attieke processing equipment to the customer in Côte d'Ivoire

-

Henan Jinrui Successfully Ships Cassava Flour Processing Line to Madagascar Client

Henan Jinrui Successfully Ships Cassava Flour Processing Line to Madagascar Client

-

Henan Jinrui Advanced Cassava Starch Processing Equipment Wins Over Nigerian Food Processor

Henan Jinrui Advanced Cassava Starch Processing Equipment Wins Over Nigerian Food Processor

-

Henan Jinrui Delivers Custom 1TPD Garri & Attieke Making Equipment to Benin

Henan Jinrui Delivers Custom 1TPD Garri & Attieke Making Equipment to Benin

-

Henan Jinrui Secures Order from Benin for 1-Ton Daily Garri and Attieke Processing Machines

Henan Jinrui Secures Order from Benin for 1-Ton Daily Garri and Attieke Processing Machines

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others