Tel/WhatsApp

Tel/WhatsApp

Vibration sieve for cassava flour production

- Introduction

- Parameter

Vibration sieve applications:

Vibration sieve is suitable for all kinds of powders , particles and liquids. Widely used in fertilizer, medicine and powder coatings, starch, wheat flour, rice flour, and other processing industries. Doing factory vibration sieve is a professional sieve machine for flour and starch sieving and production, meet your requests of flour and starch production requests.

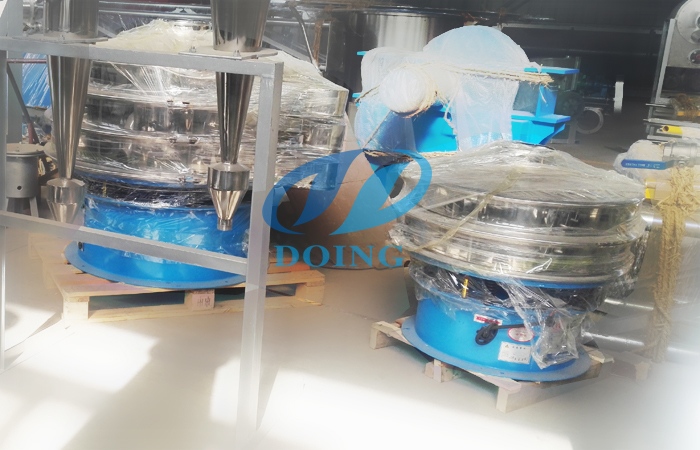

Doing factory vibration sieve

Vibration sieve main features:

1. High efficiency in sieve separation and filtering precision, suitable for all kinds of powders, particles and liquids.

2. With bounce ball, no block of sieve nets , the finest sieving degree is 400mesh per inch

3. Quickly to release the ring in vibration sieve, the net change is fast and flexible.

4. Mirror polished dust proof lid, free from powder pollution and liquid overflowing, low noise during the production process.

5. The feeding-out direction can be selected freely.

6. Top quality vibration motor, APO protected, prevent motor damaged from short circuit, unstable voltage or default phases.

Vibration sieve structures:

The vibration sieve is composed of dustproof cover, sieve frame, sieve cloth, clamp, silicon sealing strip, damping spring, vibration motor and basement.

Vibration sieve structures

Vibration sieve working principles:

Vibration sieve used vertical vibration motor as vibration source, there are two accentric blocks fixed on the motor shaft, can produce horizontal, vertical, inclined three dimensional motion by adjusting the phase angle between the two eccentric blocks, effected different centrifugal force, then material's moving trails changed, achieve sieveing purpose.

- Introduction

- Parameter

Accept customized of this vibration sieve:

Voltage: 110V-550V, single phase/three phase, 50HZ/60HZ

Material: Full stainless steel, or carbon steel with contact part stainless steel

Sieve layers quantity: 1-5 layers

Sieve diameter size: 450mm--2000mm

Sieve mesh: 2-500 mesh/inch

-

Reasons for excessive impurities in cassava starch production

Reasons for excessive impurities in cassava starch production

-

Main Factors Influencing the Price of Cassava Starch Processing Equipment

Main Factors Influencing the Price of Cassava Starch Processing Equipment

-

Tips for buying fufu making machine

Tips for buying fufu making machine

-

How to transform cassava into cassava slices?

How to transform cassava into cassava slices?

-

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

-

What should I pay attention to for reducing starch loss during cassava starch production?

What should I pay attention to for reducing starch loss during cassava starch production?

-

Common Problems and Solutions During Cassava Starch Production

Common Problems and Solutions During Cassava Starch Production

-

How Does a Cassava Grinder Work?

How Does a Cassava Grinder Work?

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others