Tel/WhatsApp

Tel/WhatsApp

What should I pay attention to for reducing starch loss during cassava starch production?

Reducing starch loss during cassava starch production is crucial for improving yield and efficiency. Here are key factors to pay attention to:

- Freshness of Cassava:Use fresh cassava roots to minimize starch degradation. Stored cassava loses starch due to respiration and microbial activity.

- Variety Selection: Choose high-starch-content cassava varieties (e.g., TME 419, KU 50).

- Remove Impurities: Dirt, sand, and peels can interfere with extraction, leading to cassava starch loss.

-Primary Cleaning: Use cassava dry sieve to remove dirt, weeds and mud without damaging the cassava tubers.

-Thorough Washing: Using a paddle washer in the cleaning step of cassava starch production can wash the residues on the surface of cassava roots thoroughly.

paddle washer

paddle washer

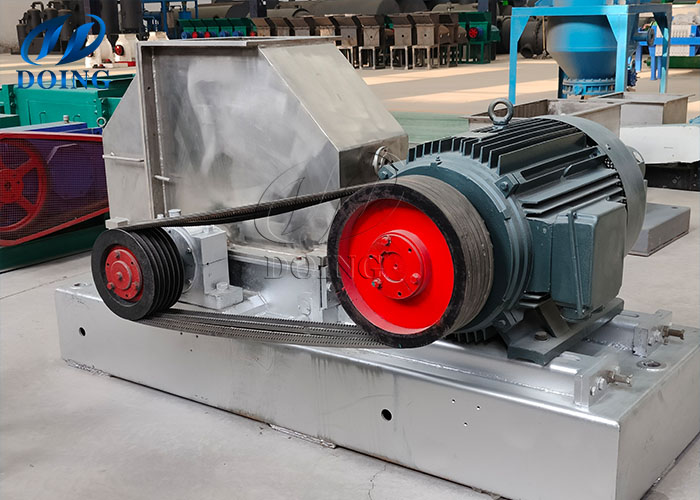

- Fine Grinding: Ensure complete cell rupture to release cassava starch granules, but avoid over-grinding, which can break starch molecules.

- Use Modern Cassava Rasper: The rasping machine in cassava starch production line can improve starch release efficiency compared to traditional method or hammer mill. Rasper is the most efficiency equipment for crushing cassava tubers in starch project.

- Water Usage Balance: Too much water dilutes cassava starch, while too little reduces extraction rate.

cassava starch rasper

cassava starch rasper

- Multi-stage Sieving:Use several stages of centrifugal sieves in cassava starch processing line to separate starch from fibers effectively.

- Residual Starch in cassava fiber: Re-process cassava fiber (waste pulp) to recover remaining starch.

centrifuge sieve

centrifuge sieve

- Fast Sedimentation:Use settling tanks or 18-stage hydrocyclone station to separate protein and cell fluid out of starch quickly, preventing fermentation.

- Proper Dewatering: Use a peeler centrifuge to reduce moisture before drying.

hydrocyclone station

hydrocyclone station

- Controlled Temperature (≤60°C): High heat can gelatinize cassava starch, reducing quality.

- Even Drying: Flash dryer in cassava starch production line can prevent uneven moisture content. And through automatic interlocking system, moisture content of final starch can be controlled.

flash dryer

flash dryer

- Starch Recovery from Wastewater: Use sedimentation ponds or decanters to reclaim residual cassava starch.

- Recycle Water: Reuse process water after filtration to minimize starch loss.

- Regular Cleaning: Prevent microbial growth and clogging in pipelines and machines.

- Automated Control Systems: Ensure consistent processing conditions (e.g., pH, water ratio).

- Train Workers on best practices to avoid unnecessary starch loss.

- Monitor Key Parameters: Starch concentration, extraction rate, and moisture content at each stage.

By optimizing these steps, starch loss in cassava starch production line can be significantly reduced, thus improving profitability. Henan Jinrui company is professional manufacturer and supplier of cassava starch production line, with more than 10 years’ experience. If you’d like specific recommendations for equipment or process adjustments, feel free to contact us any time!

-

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

-

What should I pay attention to for reducing starch loss during cassava starch production?

What should I pay attention to for reducing starch loss during cassava starch production?

-

Common Problems and Solutions During Cassava Starch Production

Common Problems and Solutions During Cassava Starch Production

-

How Does a Cassava Grinder Work?

How Does a Cassava Grinder Work?

-

Advantages of cassava peeler used for cassava agriculture

Advantages of cassava peeler used for cassava agriculture

-

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

-

The benefits of hydrocyclone station in starch industrial processes

The benefits of hydrocyclone station in starch industrial processes

-

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

-

How to increase output in garri processing?

How to increase output in garri processing?

-

Comparison of Cassava and Potato Starch Production Lines

Comparison of Cassava and Potato Starch Production Lines

-

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

-

Selling High-Quality Cassava Processing Equipment to Uganda

Selling High-Quality Cassava Processing Equipment to Uganda

-

Gari processing line successfully shipped to Nigeria

Gari processing line successfully shipped to Nigeria

-

Cassava starch fine fiber sieve purchased by Indian client

Cassava starch fine fiber sieve purchased by Indian client

-

Gari making plants were transported to Ghana from Henan Jinrui’s factory

Gari making plants were transported to Ghana from Henan Jinrui’s factory

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others