Tel/WhatsApp

Tel/WhatsApp

Cassava starch processing machinery manufacturer

- Introduction

Cassava starch processing machinery introduction:

Cassava starch is a kind of white powder of tapioca that is dehydrated and dried after starch extraction. It is widely used in food industry and non-food industry. Cassava starch production is a very promising market. Doing company mainly engaged in the design, processing and manufacturing of the starch equipment, and make installation and commissioning for the supporting projects. We are a professional cassava starch processing machinery manufacturers.

Cassava starch wide aoolications

Cassava starch processing machinery process:

Technical process:

Fresh cassava - Cassava cleaning and washing - Grinding - Starch extraction - Filtering and desanding - Starch concentration and purification - Dewatering - Drying

Machine order:

Dry sieve - Paddle washer - Cutting machine - Rasper - Centrifuge sieve - Fine fiber sieve - Disc separator - Hydrocyclone - Vacuum filter - Flash dryer

Cassava starch machinery process

Main equipments and its function in this cassava starch processing machinery:

1) Cleaning parts of cassava starch processing machinery:

Dry sieve: Widely used in impurities pre-removal for starch production. It's used to remove dirt, sand, small stones, weeds and other impurities that are attached on the surface of potato, sweet potato and cassavas.

Paddle washer: Mainly used to wash the raw materials. Adopted countercurrent washing principle. By the effect of paddle pushing, the raw material flows in the converse direction against water currently, which makes washing completely and eliminate sand and mud at most.

Cassava cage cleaner and paddle washer

2) Crushing parts of cassava starch processing machinery:

Cutting machine: Its main function is cut cassavas into small pieces, 3-5cm, for further processing.

Rasper: Break the materials, crush cassavas into slurry, release starch particles from cell, with high starch dissociation rate.

Cassava cutting machine and rasper

3) Starch extraction of cassava starch processing machinery:

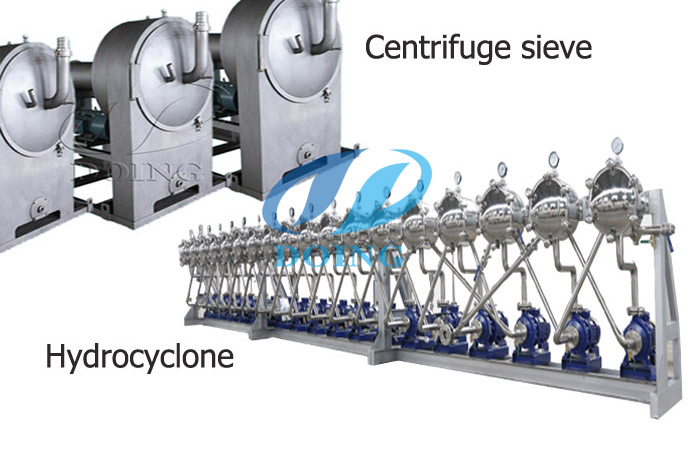

Centrifuge sieve: Used for the extraction of starch from the materials, remove fiber from starch slurry, high starch extraction rate.

4) Starch filtering and desanding of cassava starch processing machinery:

Fine fiber sieve: It is a machine mainly for separating small particles of fiber from starch slurry. This process is achieved by gravity of the slurry and screen mesh inside the drum.

Starch centrifuge sieve and hydrocyclone

5) Starch concentration and purification of cassava starch processing machinery:

Disc separator: It is widely used in processing of starch to separate protein and cell liquid out of slurry, with high separating factor.

Hydrocyclone: It is designed to get rid of related substances such as fiber and protein in the starch milk. For the starch's washing, concentration and purification.

Usually suggest this two machine used in combination, make the production high efficiency and high quality.

Cassava starch drying system

6) Drying system of cassava starch processing machinery:

Vacuum filter: Widely used for the starch dewatering, final starch water content is 38%-42%.

Flash dryer: This is the last step for tapioca starch production. It adopts low temperature drying system, which will prevent starch gelatinization. Final starch water content is 12%-14%.

Above all, its all main complete cassava starch processing machinery, and our factory is a good cassava starch processing machinery manufacturer.

PREV:Cassava starch processing machinery

PREV:Cassava starch processing machinery

NEXT:Nothing

NEXT:Nothing

-

Tips for buying fufu making machine

Tips for buying fufu making machine

-

How to transform cassava into cassava slices?

How to transform cassava into cassava slices?

-

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

-

What should I pay attention to for reducing starch loss during cassava starch production?

What should I pay attention to for reducing starch loss during cassava starch production?

-

Common Problems and Solutions During Cassava Starch Production

Common Problems and Solutions During Cassava Starch Production

-

How Does a Cassava Grinder Work?

How Does a Cassava Grinder Work?

-

Advantages of cassava peeler used for cassava agriculture

Advantages of cassava peeler used for cassava agriculture

-

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others