Tel/WhatsApp

Tel/WhatsApp

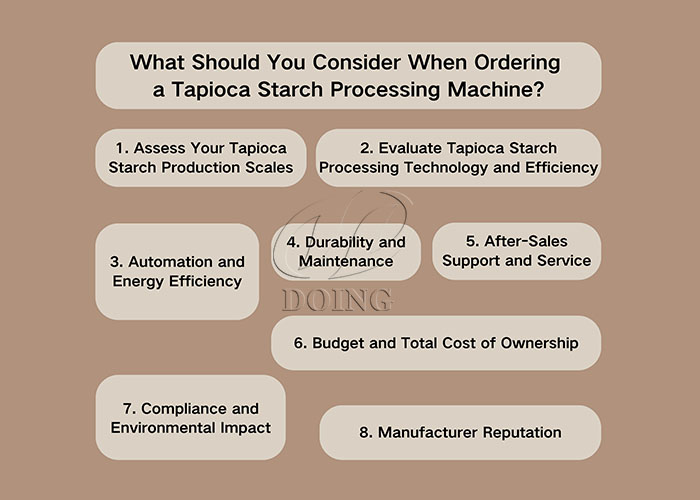

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

Starting a tapioca starch processing business requires strategic investment in the right machine. The efficiency, profitability, and sustainability of your operation depend heavily on the starch equipment you choose. Here are key factors to consider before ordering a tapioca starch processing machine:

factors you should consider whrn ordering tapioca starch processing machine

factors you should consider whrn ordering tapioca starch processing machine

>1. Assess Your Tapioca Starch Production Scales

Before ordering a tapioca starch machine, you firstly should evaluate your production scale. Are you targeting small, medium, or large-scale output? Cassava starch machinery vary in capacity—from 5–10 tons per day for startups to 50–100+ tons for industrial operations. Overestimating capacity leads to unnecessary costs, while underestimating limits growth. At Henan Jinrui, we can provide tapioca starch machine processing 2-40 tons cassava input per hour, suitable for different needs.

>2. Evaluate Tapioca Starch Processing Technology and Efficiency

A high-quality tapioca starch machine should cover all critical processing stages: cleaning, rasping, extraction, dewatering, drying, and packaging. Advanced technology ensures higher starch extraction rates (above 95%) and purity (minimizing impurities). Look for features like centrifugal sieves, hydrocyclone stations, and automated drying systems to maximize yield and product quality. For instance, adopting 18-stages extraction technology and unifying recycle, refinery, and concentration, Henan Jinrui’s hydrocyclone stations can greatly improve the starch yield as well as reducing starch loss.

tapioca starch processing machine

tapioca starch processing machine

>3. Automation and Energy Efficiency

Automation reduces labor costs and human error, ensuring consistent output. Semi- or fully automated tapioca starch processing systems streamline operations, from feeding cassava to packaging starch. Equally important is energy efficiency—tapioca starch processing machines with heat recovery systems or low-water consumption cut long-term operational costs.

>4. Durability and Maintenance

Invest in robust, corrosion-resistant tapioca starch extraction machines built from food-grade stainless steel. Easy maintenance access and readily available spare parts minimize downtime. Ask about the expected lifespan and service intervals. Reputable manufacturers provide detailed maintenance guidelines and training. For example, Henan Jinrui provide free online guide for installation and one-year free maintenance service.

>5. After-Sales Support and Service

Reliable technical support is crucial. Ensure the supplier of tapioca starch processing machines offers installation supervision, operator training, and prompt troubleshooting. Warranty periods and a global service network add value. Backed up by our engineering team, Nigerian branch office, local built manufacturing factory, we, Henan Jinrui can promptly address issues and offer services.

nigerian branch office

nigerian branch office

>6. Budget and Total Cost of Ownership

While upfront cost matters, prioritize long-term value. Cheap tapioca starch processing machines may save initially but incur higher repair and energy costs. Calculate ROI by comparing efficiency, durability, and operational savings.

>7. Compliance and Environmental Impact

Ensure the tapioca starch processing machinery meets ISO, CE, or local food safety certifications. Eco-friendly features like wastewater recycling systems or reduced emissions align with sustainability goals and regulatory requirements, enhancing your market reputation.

>8. Manufacturer Reputation

Research the manufacturer’s track record. Reviews, case studies, and client testimonials reveal reliability. Established brands like Henan Jinrui offer tailed solutions, with decades of expertise and flexible configurations for unique needs.

The above is some key factors you could consider when ordering a tapioca starch processing machine. If you wanna learn the price, you can chat with our sales manager and engineer who will design a solution tailed to your demand and offer the accordingly quotation!

-

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

-

What should I pay attention to for reducing starch loss during cassava starch production?

What should I pay attention to for reducing starch loss during cassava starch production?

-

Common Problems and Solutions During Cassava Starch Production

Common Problems and Solutions During Cassava Starch Production

-

How Does a Cassava Grinder Work?

How Does a Cassava Grinder Work?

-

Advantages of cassava peeler used for cassava agriculture

Advantages of cassava peeler used for cassava agriculture

-

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

-

The benefits of hydrocyclone station in starch industrial processes

The benefits of hydrocyclone station in starch industrial processes

-

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

-

How to increase output in garri processing?

How to increase output in garri processing?

-

Comparison of Cassava and Potato Starch Production Lines

Comparison of Cassava and Potato Starch Production Lines

-

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

-

Selling High-Quality Cassava Processing Equipment to Uganda

Selling High-Quality Cassava Processing Equipment to Uganda

-

Gari processing line successfully shipped to Nigeria

Gari processing line successfully shipped to Nigeria

-

Cassava starch fine fiber sieve purchased by Indian client

Cassava starch fine fiber sieve purchased by Indian client

-

Gari making plants were transported to Ghana from Henan Jinrui’s factory

Gari making plants were transported to Ghana from Henan Jinrui’s factory

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others