Tel/WhatsApp

Tel/WhatsApp

The benefits of hydrocyclone station in starch industrial processes

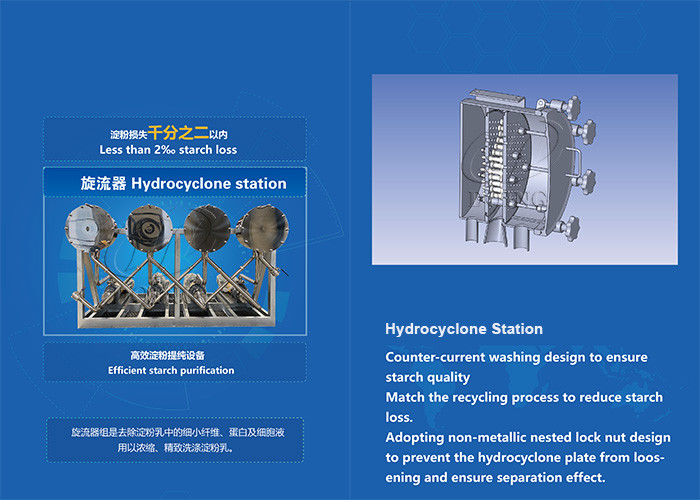

In the industrial processes, particularly in the starch processing, the hydrocyclone station has emerged as a pivotal technology for purification and separation. The hydrocyclone station, a device designed to separate particles from a liquid based on their density and size, offers a multitude of benefits that enhance efficiency, reduce costs, and improve product quality. Here, Henan Jinrui will delve into the key benefits of incorporating a hydrocyclone station into industrial processes, especially in starch production.

Hydrocyclone station

Hydrocyclone station

The most key benefit of hydrocyclone station is enable to effectively separate starch from other impurities such as proteins, fibers, and other non-starch components. The centrifugal force generated within the hydrocyclone station allows for the precise separation of particles based on their size and density to obtain high quality starch. The hydrocyclone station designed by Henan Jinrui adopts 18-stage series device, the purity of the processed starch can reach 98%, which can achieve effective separation and purification effects.

A major benefit of hydrocyclone station is the relatively low operational costs for starch production compared to other traditional separation technologies. Hydrocyclone station do not require moving parts, which minimizes maintenance and repair expenses. Additionally, the compact design of hydrocyclone station from Henan Jinrui reduces the need for large installation spaces, further cutting down on infrastructure costs.

The benefit of energy saving is also one of the reasons why hydrocyclone station is popular in starch processing. Hydrocyclone station operates using the natural force of the liquid flow in starch production, which means it consumes less energy compared to mechanical separation methods. This energy efficiency not only lowers operational costs but also aligns with sustainable industrial practices, reducing the overall carbon footprint of the process.

Benefits of hydrocyclone station

Benefits of hydrocyclone station

Besides, the scalability and flexibility is one of benefits of hydrocyclone station. Modular configurations design of hydrocyclone stations can be easily scaled to meet the demands of different production volumes in starch processing. Whether for small-scale operations or large industrial plants, hydrocyclones can be configured in multiple stages to achieve the desired level of purification. This flexibility makes them suitable for a wide range of applications within the starch industry and beyond.

Unlike batch processing methods, hydrocyclone station allow for continuous operation, which significantly enhances production throughput. The hydrocyclone station manufactured by Henan Jinrui can realize recovery, purification and refining in starch processing at the same time. The benefit of continuous process ensures a steady output of purified starch, reducing downtime and increasing overall productivity in starch processing.

Improving starch quality is the most important benefit of using hydrocyclone station in starch processing.The precise separation capabilities of hydrocyclone station lead to a higher quality starch. In the starch industry, this means achieving a purer starch with fewer impurities, which is essential for applications in food, pharmaceuticals, and other industries where product quality is paramount.

Starch purification equipment

Starch purification equipment

Hydrocyclone station is beneficial to establish environmental friendly starch processing industry by minimizing waste and reducing the need for chemical additives. The hydrocyclone provided by Henan Jinrui is equipped with a multi-stage recovery device, which can minimize starch loss and achieve a 90% water recovery rate. The efficient separation process ensures that fewer by-products are generated, and the recovered starch can be used more effectively, reducing overall waste.

The last benefit of hydrocyclone station in starch processing industry is easy to integrate. Hydrocyclone stations can be seamlessly integrated into existing production lines without significant modifications. This ease of integration allows industries to upgrade their purification processes without incurring substantial downtime or additional costs.

The hydrocyclone station in starch processes, offers a myriad of benefits ranging from cost savings and energy efficiency to improved product quality and environmental sustainability. By leveraging the advantages of hydrocyclone station in starch production can achieve higher efficiency, better product quality, and a more sustainable production process.

Integrating hydrocyclone station into starch purification process is not only an investment in equipment, but also a trend in the future advanced starch processing industry. If you want to purchased starch processing equipment, welcome to consult us! Henan Jinrui, with 14 years experiences of manufacturing cassava processing equipment, will be your trusted partner!

-

Common Problems and Solutions During Cassava Starch Production

Common Problems and Solutions During Cassava Starch Production

-

How Does a Cassava Grinder Work?

How Does a Cassava Grinder Work?

-

Advantages of cassava peeler used for cassava agriculture

Advantages of cassava peeler used for cassava agriculture

-

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

-

The benefits of hydrocyclone station in starch industrial processes

The benefits of hydrocyclone station in starch industrial processes

-

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

-

How to increase output in garri processing?

How to increase output in garri processing?

-

Comparison of Cassava and Potato Starch Production Lines

Comparison of Cassava and Potato Starch Production Lines

-

Which factors will influence the manioc starch yield for cassava starch production?

Which factors will influence the manioc starch yield for cassava starch production?

-

Cassava Chips Machinery: Best Practices for Scaling Up Production

Cassava Chips Machinery: Best Practices for Scaling Up Production

-

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

-

Selling High-Quality Cassava Processing Equipment to Uganda

Selling High-Quality Cassava Processing Equipment to Uganda

-

Gari processing line successfully shipped to Nigeria

Gari processing line successfully shipped to Nigeria

-

Cassava starch fine fiber sieve purchased by Indian client

Cassava starch fine fiber sieve purchased by Indian client

-

Gari making plants were transported to Ghana from Henan Jinrui’s factory

Gari making plants were transported to Ghana from Henan Jinrui’s factory

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others