Tel/WhatsApp

Tel/WhatsApp

Comparison of Cassava and Potato Starch Production Lines

Both cassava and potato starch are vital ingredient in food, pharmaceuticals, textiles, and biofuels. While they share similarities in their applications and processing procedure, their production processes differ significantly due to raw material properties and end-product requirements. This article will offer a comparison of cassava and potato starch production lines.

Cassava and potato starch production follow a similar framework:

cleaning-washing-grinding-separating-refining-dewatering-drying-sieving-packing, but machines in some processing stages are different.

cassava starch production line

cassava starch production line

Main Similarities Between Cassava and Potato Starch Production Lines

Cleaning: Raw materials are primarily cleaned by a dry sieve to remove dirt, stones, and debris.

Grinding: Both cassava and potato will be grind into mash by a cassava rasper

Separating: Cassava and potato starch slurry is extracted by a centrifugal sieve to remove fibers

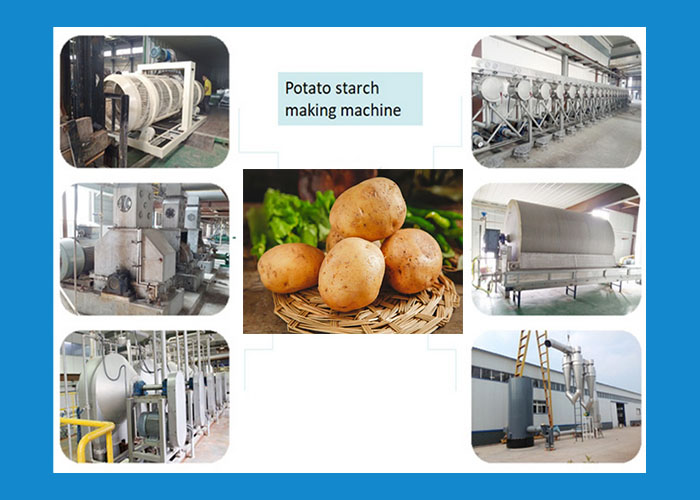

potato starch production line

potato starch production line

Refining: Cassava and potato starch slurry is purified using hydrocyclone stations to remove proteins, cell and impurities.

Drying: Flash or airflow dryers produce a fine, dry starch powder.

Sieving: a sifter sieve helps to screen coarse starch granule and qualified starch powder.

Packaging: The final product is sieved, graded, and packed.

Key Differences Between Cassava and Potato Starch Production Lines

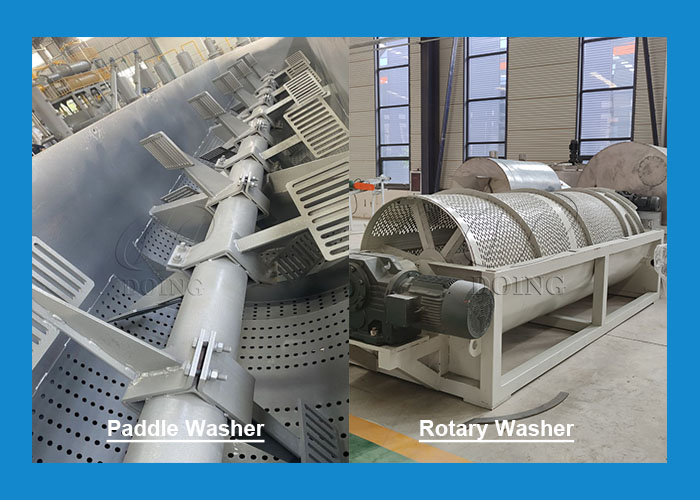

Washing: a paddle washer is often used in cassava starch production line to tail large stick-shape cassava tubers as well as removing part cassava peels; while a rotary washer is usually configured in the potato starch production line to wash small potatoes as well as reducing starch loss by avoiding the damage of potato peels.

paddle washer and rotary washer

paddle washer and rotary washer

Separating: in cassava starch production line, a fine fiber sieve is often added for further removing large and coarse fibers and ensuring starch taste due to the large fiber content in cassava tubers

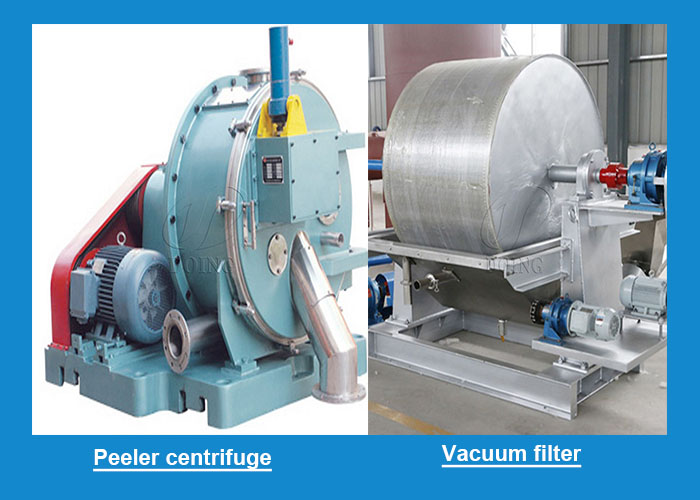

Dewatering: in cassava starch production line, a peeler centrifuge is a common dewatering machine, which is suitable for fine starch granule production like cassava starch(its fineness is 5–35 µm), corn starch, and wheat starch etc. However, in potato starch(its fineness is15–100 µm) production line, a vacuum filter is more popular among clients for its cheaper advantage.

peeler centrifuge and vacuum filter

peeler centrifuge and vacuum filter

The above is the comparison of cassava and potato starch production line, if you want to process cassava starch or potato starch, you can chat with us! Henan Jinrui, experienced in starch machinery manufacture for over 10 years, can offer a station solution design for you, catering to your different demands!

-

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

-

What should I pay attention to for reducing starch loss during cassava starch production?

What should I pay attention to for reducing starch loss during cassava starch production?

-

Common Problems and Solutions During Cassava Starch Production

Common Problems and Solutions During Cassava Starch Production

-

How Does a Cassava Grinder Work?

How Does a Cassava Grinder Work?

-

Advantages of cassava peeler used for cassava agriculture

Advantages of cassava peeler used for cassava agriculture

-

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

-

The benefits of hydrocyclone station in starch industrial processes

The benefits of hydrocyclone station in starch industrial processes

-

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

-

How to increase output in garri processing?

How to increase output in garri processing?

-

Comparison of Cassava and Potato Starch Production Lines

Comparison of Cassava and Potato Starch Production Lines

-

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

-

Selling High-Quality Cassava Processing Equipment to Uganda

Selling High-Quality Cassava Processing Equipment to Uganda

-

Gari processing line successfully shipped to Nigeria

Gari processing line successfully shipped to Nigeria

-

Cassava starch fine fiber sieve purchased by Indian client

Cassava starch fine fiber sieve purchased by Indian client

-

Gari making plants were transported to Ghana from Henan Jinrui’s factory

Gari making plants were transported to Ghana from Henan Jinrui’s factory

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others