Tel/WhatsApp

Tel/WhatsApp

Home>FAQ>Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

Home>FAQ>Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

Cassava chips are sliced, dried pieces of cassava tubers, typically 5–8mm thick. They have emerged as a critical raw material for industrial applications, such as ethanol production, animal feed manufacturing, and biofuel processing. Their long shelf life, ease of storage, and high energy content make them indispensable in these sectors. At Henan Jinrui Food Company, we specialize in designing advanced cassava chips processing equipment tailored to meet both small-scale and industrial needs. Next, we will explore the equipment solutions for cassava chips processing in detail.

cassava chips processing

cassava chips processing

How to Process Cassava Chips: Step-by-Step

A modern cassava chips processing line automates the following stages:

Cleaning: Fresh cassava tubers are fed into a dry sieve equipme to remove dirt, stones, and debris.

Peeling (Optional): Depending on end-use, peeling can be added to enhance chip quality.

Chipping: Tubers are sliced uniformly into 5–8mm chips using high-speed cassava chipping equipment.

Drying: Chips are sun-dried or mechanically dried to reduce moisture for long-term storage.

Our cassava chips processing lines are modular, allowing customization based on your production goals.

Processing Capacity: From 1 Ton to 25 Tons Per Hour

cassava chips line

cassava chips line

Henan Jinrui’s cassava chips processing equipment caters to businesses of all sizes:

Small-Scale Cassava Chips Processing Line: Process 1–5 tons of cassava per hour, ideal for startups or rural cooperatives.

Mid-Scale Cassava Chips Processing Line: Handle 6–15 tons/hour, perfect for expanding enterprises.

Industrial Cassava Chips Processing Line: Achieve up to 25 tons/hour with dual chipping machines and automated conveyors, designed for large factories.

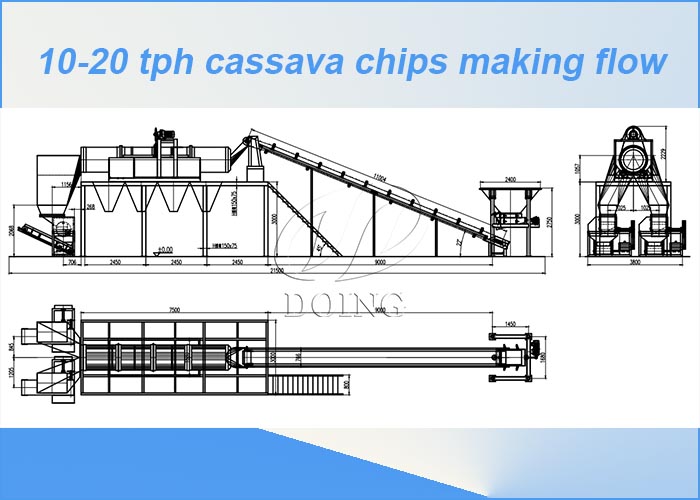

cassava chips making flow drawup

cassava chips making flow drawup

Key Cassava Chips Processing Equipment Includes:

Feeding Hopper: Ensures consistent tuber supply.

Belt Conveyor: Transports cassava between machines.

Dry Sieve Machine: Cleans tubers efficiently.

Chipping Machines: Dual units for high-volume output.

cassava chips production line

cassava chips production line

Industrial Applications of Dried Cassava Chips

Animal Feed: Cassava chips are rich in carbohydrates, making them an affordable energy source for livestock.

Ethanol Production: A key raw material for biofuel and alcohol industries.

Starch Extraction: Chips can be further processed into industrial-grade starch.

Export Commodity: High demand in global markets, particularly in Southeast Asia, West Africa, South America,etc.

From small farms to industrial factories, cassava chips processing offers lucrative opportunities. Henan Jinrui Company equips you with cutting-edge technology, local expertise, and reliable support to thrive in cassava chips processing business. If you have interest, warmly welcome to chat with us!

-

Common Problems and Solutions During Cassava Starch Production

Common Problems and Solutions During Cassava Starch Production

-

How Does a Cassava Grinder Work?

How Does a Cassava Grinder Work?

-

Advantages of cassava peeler used for cassava agriculture

Advantages of cassava peeler used for cassava agriculture

-

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

-

The benefits of hydrocyclone station in starch industrial processes

The benefits of hydrocyclone station in starch industrial processes

-

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

-

How to increase output in garri processing?

How to increase output in garri processing?

-

Comparison of Cassava and Potato Starch Production Lines

Comparison of Cassava and Potato Starch Production Lines

-

Which factors will influence the manioc starch yield for cassava starch production?

Which factors will influence the manioc starch yield for cassava starch production?

-

Cassava Chips Machinery: Best Practices for Scaling Up Production

Cassava Chips Machinery: Best Practices for Scaling Up Production

-

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

-

Selling High-Quality Cassava Processing Equipment to Uganda

Selling High-Quality Cassava Processing Equipment to Uganda

-

Gari processing line successfully shipped to Nigeria

Gari processing line successfully shipped to Nigeria

-

Cassava starch fine fiber sieve purchased by Indian client

Cassava starch fine fiber sieve purchased by Indian client

-

Gari making plants were transported to Ghana from Henan Jinrui’s factory

Gari making plants were transported to Ghana from Henan Jinrui’s factory

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others