Tel/WhatsApp

Tel/WhatsApp

How do you get starch from cassava?

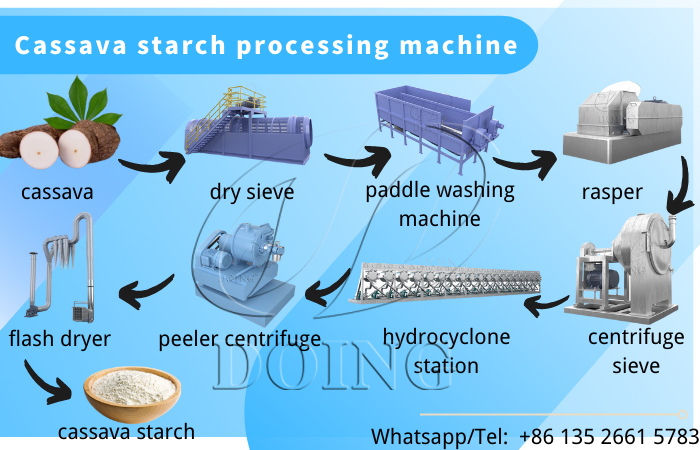

Cassava starch processing machines and process flow

Cassava starch processing machines and process flow

First step: cleaning

First of all, using the dry sieve to remove the dirt, sand, small stones, weeds and other impurities on the surface of cassava.

Second step: washing

Cassava paddle washing machine

Cassava paddle washing machine

Then using paddle washing machine to make the cassava washing completely and eliminate sand and mud effectively.

Third step: crushing

After washing, using cutting machine and rasper to crush the cassava into cassava slurry. This step is extremely important, which can crush cassava to the maximum extent and free the binding starch, which is the key step to improve the yield of cassava starch.

Cassava crushing machine

Cassava crushing machine

Fourth step: separating

Using centrifuge sieve to separate the fiber and starch slurry, and then using fine fiber sieve to separate small fiber further.

Cassava fine fiber sieve

Cassava fine fiber sieve

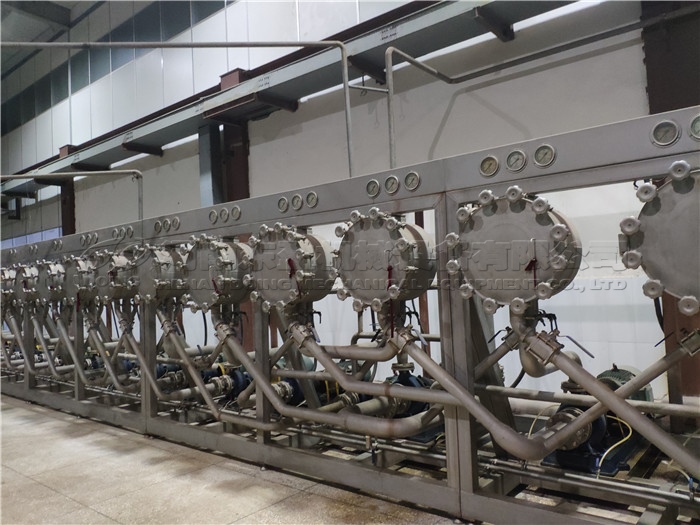

Fifth step: concentrating

In concentrating step, using hydrocyclone station to remove fiber, protein and cell sap out of starch milk to concentrate and delicate scrubbing starch milk.

Cassava hydrocyclone station

Cassava hydrocyclone station

Sixth step: dehydrating

Using peeler centrifuge to make the solid-liquid separation. That’s the dehydration step of starch milk, after this step, you can get the wet cassava starch. Peeler centrifuge can shorten the dehydrating time, increase production capacity by 50% and decrease moisture content to 36.5%.

Seventh step: drying

Using flash dryer to dry the wet cassava starch into final cassava starch product. Flash dryer is equipped with special negative pressure system and cooling system, which can not only control the loss of cassava starch, but also guarantee the moisture uniformity of the finished starch.

Cassava flash dryer

Cassava flash dryer

That’s the whole cassava starch production process. If you have any investing ides about cassava starch processing plant, please contact Henan Jinrui, who had helped clients successfully install the cassava starch project in more than 30 countries, like Nigeria, Tanzania, Indonesia, Ghana, South Africa, etc. Our professional engineers can not only customize you high starch extraction rate cassava starch processing machine, but also offer you equipment debugging,technical installation instruction, worker training, etc.

-

Reasons for excessive impurities in cassava starch production

Reasons for excessive impurities in cassava starch production

-

Main Factors Influencing the Price of Cassava Starch Processing Equipment

Main Factors Influencing the Price of Cassava Starch Processing Equipment

-

Tips for buying fufu making machine

Tips for buying fufu making machine

-

How to transform cassava into cassava slices?

How to transform cassava into cassava slices?

-

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

-

What should I pay attention to for reducing starch loss during cassava starch production?

What should I pay attention to for reducing starch loss during cassava starch production?

-

Common Problems and Solutions During Cassava Starch Production

Common Problems and Solutions During Cassava Starch Production

-

How Does a Cassava Grinder Work?

How Does a Cassava Grinder Work?

-

Advantages of cassava peeler used for cassava agriculture

Advantages of cassava peeler used for cassava agriculture

-

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

-

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

-

Selling High-Quality Cassava Processing Equipment to Uganda

Selling High-Quality Cassava Processing Equipment to Uganda

-

Gari processing line successfully shipped to Nigeria

Gari processing line successfully shipped to Nigeria

-

Cassava starch fine fiber sieve purchased by Indian client

Cassava starch fine fiber sieve purchased by Indian client

-

Gari making plants were transported to Ghana from Henan Jinrui’s factory

Gari making plants were transported to Ghana from Henan Jinrui’s factory

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others