Tel/WhatsApp

Tel/WhatsApp

What is the potato starch production process ?

Potato is a widely planted economic crop and the fourth largest crop after wheat, rice and corn. The starch content in fresh potatoes is generally 9%~25%. Due to its low viscosity, aging resistance and good elasticity, potato starch is widely used in food, medicine, chemicals, textiles, papermaking, feed casting, oil drilling and other fields. How to extract starch from potato starch? Under normal circumstances, the production process of potato starch is completed by the cooperation of advanced potato starch processing machines.

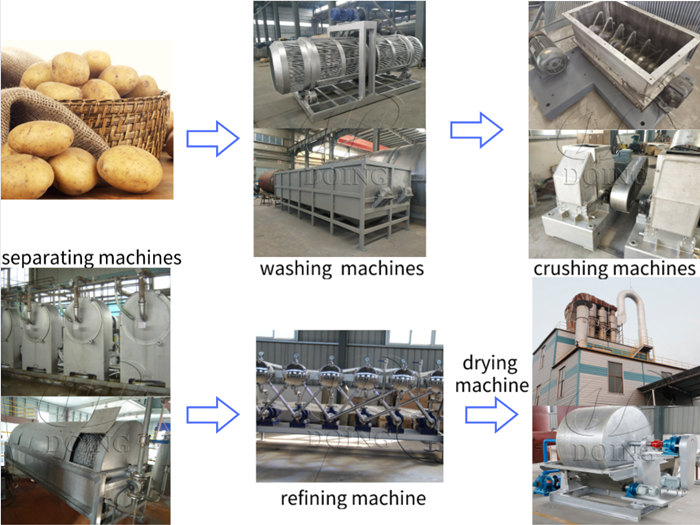

Potato starch production process and processing machines

Potato starch production process and processing machines

First, use belt conveyors and potato washing machines to transport and purify cassava.

The potato raw materials are transported from field to the designated workstations in the workshop using belt conveyor to facilitate subsequent processing. In the process of conveying, gravel, debris and other impurities are removed by dry sieve and paddle washing machine.

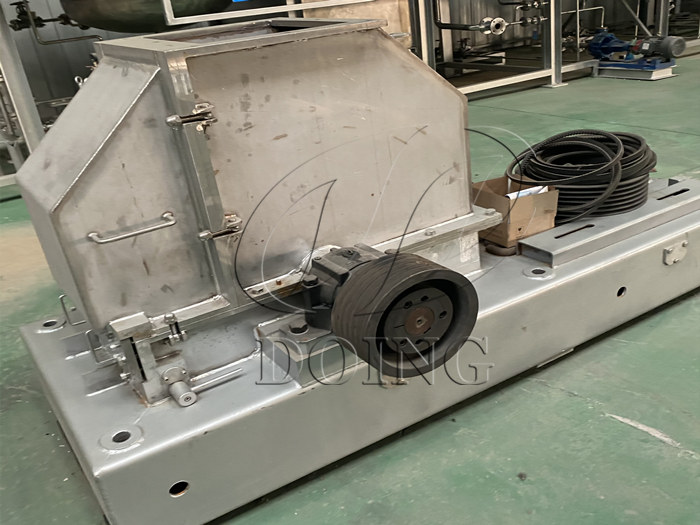

Then, potato were crushing by cutting machine and rasper machine.

The potato is crushed by these two crushing machine. High-speed rotating blade ensures crushing rate of the potato cells, so that the combined starch can be fully released as much as possible.

Potato crushing machine--rasper machine

Potato crushing machine--rasper machine

After that, potato fiber were separatedand potato starch was washed.

This potato starch production process is mainly realized by a group of machines called centrifuge sieve. The equipment adopts counter-current washing, which not only saves water consumption but also improves the potato starch concentration. If you want to make your potato starch higher purity, you can additionally use fine fiber sieve and centrifuge sieve together.

What's more, to refine and concentrate potato starch slurry.

The refinement and concentrition of potato starch slurry is mainly finished through the hydrocyclone station. Hydrocyclone station can remove the protein, fat, inorganic ash and other substances in the potato starch slurry, and at the same time, the potato starch slurry is concentrated .

Potato starch refining machine--hydrocyclone

Potato starch refining machine--hydrocyclone

Finally, dehydrating and drying potato starch

Purified potato starch slurry is pumped into vacuum filter machine for dewatering, you can get wet starch with moisture content around 40%. Then flash dryer is used to dry potato starch completely to meet standard requirement for selling.

The entire potato starch production process requires the close cooperation of various potato starch processing machines to run smoothly. Therefore, in the actual potato starch production process, engineers with rich experience are required to debug and test each potato starch processing machine. Henan Jinrui has engineers with more than 20 years of experience in the field of potato starch processing. Therefore, whether it is from process technology, machine manufacturing, machine installation or machine debugging, we can provide you with professional advice and provide appropriate solutions.

-

Reasons for excessive impurities in cassava starch production

Reasons for excessive impurities in cassava starch production

-

Main Factors Influencing the Price of Cassava Starch Processing Equipment

Main Factors Influencing the Price of Cassava Starch Processing Equipment

-

Tips for buying fufu making machine

Tips for buying fufu making machine

-

How to transform cassava into cassava slices?

How to transform cassava into cassava slices?

-

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

-

What should I pay attention to for reducing starch loss during cassava starch production?

What should I pay attention to for reducing starch loss during cassava starch production?

-

Common Problems and Solutions During Cassava Starch Production

Common Problems and Solutions During Cassava Starch Production

-

How Does a Cassava Grinder Work?

How Does a Cassava Grinder Work?

-

Advantages of cassava peeler used for cassava agriculture

Advantages of cassava peeler used for cassava agriculture

-

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

-

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

-

Selling High-Quality Cassava Processing Equipment to Uganda

Selling High-Quality Cassava Processing Equipment to Uganda

-

Gari processing line successfully shipped to Nigeria

Gari processing line successfully shipped to Nigeria

-

Cassava starch fine fiber sieve purchased by Indian client

Cassava starch fine fiber sieve purchased by Indian client

-

Gari making plants were transported to Ghana from Henan Jinrui’s factory

Gari making plants were transported to Ghana from Henan Jinrui’s factory

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others