Tel/WhatsApp

Tel/WhatsApp

Home>FAQ>Why you have to consider to choose the flash drying system from Jinrui Food Engineering Co., Ltd

Home>FAQ>Why you have to consider to choose the flash drying system from Jinrui Food Engineering Co., Ltd

Why you have to consider to choose the flash drying system from Jinrui Food Engineering Co., Ltd

In cassava flour and cassava starch processing, there are several parts from cleaning, peeling, grating, dewatering, refining, drying, milling, and sieving. In the whole process, drying is an important step to ensure to get final good quality dry cassava flour and cassava starch.

There are many kinds of dryers with various capacities. Why do you have to consider choosing the flash drying system from Jinrui Food Engineering Co., Ltd?

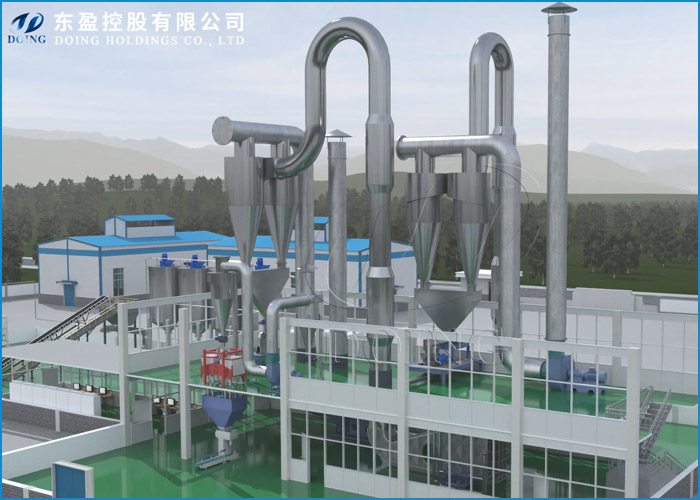

Henan Jinrui's cassava dryer

Henan Jinrui's cassava dryer

Now in the market, there are 2 kinds of main flash dryers, one is positive pressure, and the other is negative pressure. Henan Jinrui Food Company, a professional cassava processing machine manufacturer, adopts a negative pressure flash drying system in cassava processing.

The advantage of a negative pressure flash drying system is no leaking phenomenon because the inner pressure is lower than the outside. This is an important detail to ensure the final cassava flour capacity and keep the workshop clean.

Flash drying system from Jinrui

Flash drying system from Jinrui

Moreover, we use food-grade stainless steel material in the flash drying system for cassava production. There is a pulse tube design to prolong material passing time and ensure a drying effect.

What's more, there are only a few seconds from the wet cassava powder input to the final output. This ensures high drying efficiency. If customers have special needs, Jinrui can also design 2-stage drying for customers to obtain drier finished products. If you need our flash drying system to expand your cassava processing, please contact us. We are looking forward to your messages.

-

Tips for buying fufu making machine

Tips for buying fufu making machine

-

How to transform cassava into cassava slices?

How to transform cassava into cassava slices?

-

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

-

What should I pay attention to for reducing starch loss during cassava starch production?

What should I pay attention to for reducing starch loss during cassava starch production?

-

Common Problems and Solutions During Cassava Starch Production

Common Problems and Solutions During Cassava Starch Production

-

How Does a Cassava Grinder Work?

How Does a Cassava Grinder Work?

-

Advantages of cassava peeler used for cassava agriculture

Advantages of cassava peeler used for cassava agriculture

-

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

-

The benefits of hydrocyclone station in starch industrial processes

The benefits of hydrocyclone station in starch industrial processes

-

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

-

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

-

Selling High-Quality Cassava Processing Equipment to Uganda

Selling High-Quality Cassava Processing Equipment to Uganda

-

Gari processing line successfully shipped to Nigeria

Gari processing line successfully shipped to Nigeria

-

Cassava starch fine fiber sieve purchased by Indian client

Cassava starch fine fiber sieve purchased by Indian client

-

Gari making plants were transported to Ghana from Henan Jinrui’s factory

Gari making plants were transported to Ghana from Henan Jinrui’s factory

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others