Tel/WhatsApp

Tel/WhatsApp

How to process potato starch by potato starch processing equipment ?

Potato starch processing equipment

Potato starch is starch extracted from fresh potatoes. The cells of the root tubers of the potato plant contain starch grains . To extract the potato starch by potato starch processing equipment , the potatoes are crushed; the starch grains are released from the destroyed cells. The starch is then washed out and dried to potato starch powder.

How to process potato starch by potato starch processing equipment ?

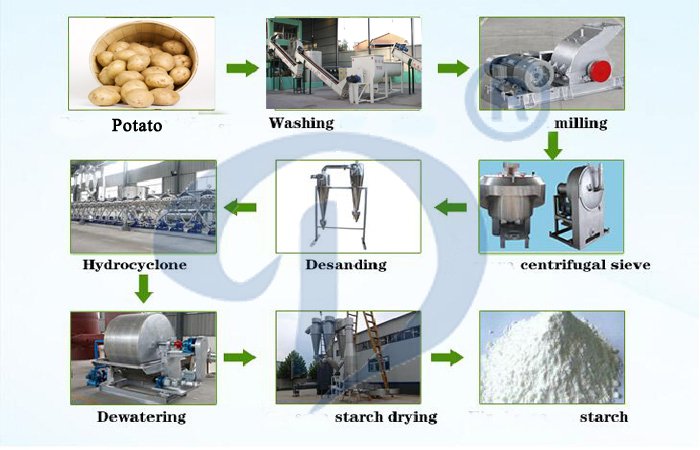

The potato starch production process of potato starch processing equipment include seveal steps : potato cleaning and washing , potato wet milling , potato starch extraction, starch milk refining, dewatering of refined starch milk and starch drying.

The complete potato starch production line

The description of potato starch production by potato starch processing equipment :

1. Potato cleaning and washing by potato starch processing equipment

The washing conveyor and the special designed washing machine will washing the fresh potato and remove the solid impurity ,such as sand ,small stone during the transportation .

2. Potato wet milling by potato starch processing equipment

The fresh potato is milled by the hammer mill with plenty of water to get the potato slurry. The purpose of the milling process is disruption of cell walls and release as much starch as possible for extracting potato starch .

Potato starch processing machine

3. Starch extraction by potato starch processing equipment

The centrifugal sieves is used to separate the starch milk and the fiber for starch extraction .

4. Starch milk refining by potato starch processing equipment

For making high quality potato starch , raw starch milk will be purified in the refining process. This involves the removal of small fibers from the starch milk and then the removal of juice water and starch milk condensation. For this purpose, the hydrocyclones are commonly used. Refining and concentration starch milk by hydro cyclones is the advanced technology in nowadays.

Potato starch dewatering machine

5. Dewatering starch milk by potato starch processing equipment

Dewatering starch milk is to remove the excess water by rotary vacuum filter, after dewatering , the wet potato starch with moisture content around 38% .

6. Starch drying by potato starch processing equipment

The potato starch drying machine will dry the wet starch with hot air in few seconds. Then, the starch is separated from hot air in cyclones. Due to short time of high temperature drying and intensive water evaporation from the starch granules, its surface is heated only to 40 °C. The potato starch after drying with moisture content around 13% .

Starch dryer machine

Above all is the simple introduction of potato starch processing machine,we could provide you the detail program according to your demand for potato starch processing plant,we also can provide you a perfect after-service systeam.To choose my company is to choose the success.

-

Common Problems and Solutions During Cassava Starch Production

Common Problems and Solutions During Cassava Starch Production

-

How Does a Cassava Grinder Work?

How Does a Cassava Grinder Work?

-

Advantages of cassava peeler used for cassava agriculture

Advantages of cassava peeler used for cassava agriculture

-

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

-

The benefits of hydrocyclone station in starch industrial processes

The benefits of hydrocyclone station in starch industrial processes

-

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

-

How to increase output in garri processing?

How to increase output in garri processing?

-

Comparison of Cassava and Potato Starch Production Lines

Comparison of Cassava and Potato Starch Production Lines

-

Which factors will influence the manioc starch yield for cassava starch production?

Which factors will influence the manioc starch yield for cassava starch production?

-

Cassava Chips Machinery: Best Practices for Scaling Up Production

Cassava Chips Machinery: Best Practices for Scaling Up Production

-

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

-

Selling High-Quality Cassava Processing Equipment to Uganda

Selling High-Quality Cassava Processing Equipment to Uganda

-

Gari processing line successfully shipped to Nigeria

Gari processing line successfully shipped to Nigeria

-

Cassava starch fine fiber sieve purchased by Indian client

Cassava starch fine fiber sieve purchased by Indian client

-

Gari making plants were transported to Ghana from Henan Jinrui’s factory

Gari making plants were transported to Ghana from Henan Jinrui’s factory

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others