Tel/WhatsApp

Tel/WhatsApp

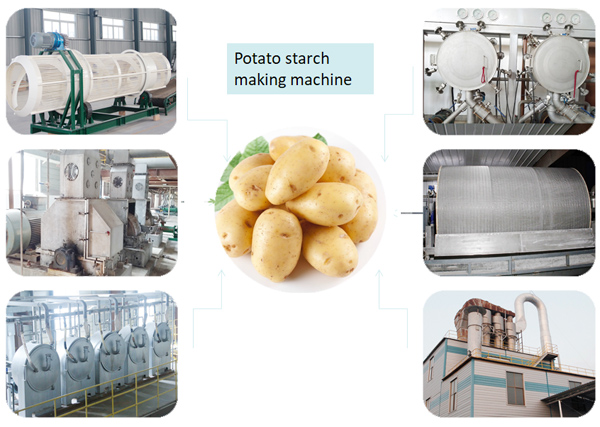

How to produce potato starch?

Potato starch is not only widely used in the food industry, but also an important industrial raw material. Doing Company is the professional manufacturer of potato deep processing equipment research and manufacturing. The potato processing equipment has been produced for more than 20 years. Our products are exported to India, South Africa, Russia, Pakistan, Vietnam and other countries. But how to produce potato starch? Here we will answer this question for you.

The process and main equipment used for how to produce potato starch

Fresh potato (conveyor)-cleaning and washing(dry sieve, rotary washing machine)-crushing (rasper)-starch slurry separation (centrifugal sieve, fine fiber sieve)-sand removal (desander) -protein separation (hydrocyclone station)-dehydration(vacuum filter)-Drying (flash dryer)

Potato starch processing machine

Potato starch processing machine

The following is the detail step for how to produce potato starch

1. Pretreatment of potato

(1)frsh potato weighing and conveying: This is the first step for how to produce potato starch. The potatoes are weighed on the weighbridge and stored in the potato yard. Then the raw materials are transported by conveyor to the potato cleaning and washing machine where the stones, sand and other attached objects are separated.

(2)Cleaning and washing: The role of this process for how to produce potato starch is mainly to remove the sediment from the outer skin of the potato, and wash away the epidermis of the roots of the potato. Cleaning the fresh potatoes as raw materials for the production of starch is the basis for ensuring the quality of the starch. The cleaner the raw material, the better the quality of the starch.

2. Extraction of potato starch

Crushing: As the most process for how to produce potato starch, the purpose of crushing is to destroy the structure of the potato, so that the tiny starch granules can be smoothly separated from the roots. The starch released from the cells is called free starch and the starch inside the cell in the dregs is called bound starch.

Potato crushing machine

Potato crushing machine

3. Starch slurry separation and refining process

(1) Starch slurry separation: For how to produce potato starch, the separation is another important procedure. We use multi stage centrifuge sieve for separating fiber from starch in potato starch processing plant. And fine fiber sieve is added for further removing the fine fibers out of starch slurry.

(2)Sand removal: The potato starch slurry comes from the fine fiber sieve is pumped by a screw pump to a desander cyclone to remove sand. This process for how to produce potato starch is mainly used to reduce the ash in potato starch so that ensures taste of starch.

(3) Protein separation: In this process, we designed a 14-stage concentrated hydrocyclone separator for how to produce potato starch. And the process water is pumped from the other end of the cyclone station to wash the starch in a countercurrent manner. The multi-stage washing can ensure the washing effect of the cyclone station, better remove the impurities such as fiber and protein contained in the starch milk.

Potato starch refining machine

Potato starch refining machine

4. Starch dehydration process

The moisture content of the starch milk coming out from the hydrocyclone station is too large to be directly dried. Therefore, how to produce potato starch, the starch milk should be dehydrated first, so that the moisture content of the starch is about 38%-40%. Vacuum filter takes use of negative pressure to complete the dehydration of starch.

5. Starch drying process

For drying process, we use starch flash dryer for the process of how to produce potato starch. The whole process time of air drying is completed in an instant, so the internal moisture of the starch granules is dried before gelatinized, and this process consists of heat transfer and mass transfer.

Potato starch drying machine

Potato starch drying machine

The above is the entire process of how to produce potato starch. Doing Company is a comprehensive company integrating R&D, production and trade. Based on the development status of China's starch industry, Doing Company fully absorbs advanced European processing technology and has independently developed domestic advanced mechanized potato starch processing machine which is sold to different counties, such as, India, Indonesia, North Korea, South Africa, Uzbekistan, Syria, Russia, Bulgaria, Algeria, Bangladesh, Pakistan, Vietnam, Thailand, Mongolia, etc. Welcome to contact us about potato starch processing machine.

-

Tips for buying fufu making machine

Tips for buying fufu making machine

-

How to transform cassava into cassava slices?

How to transform cassava into cassava slices?

-

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

How to Choose the Most Suitable Cassava Flour Milling Machine for Your Agro-Processing Factory?

-

What should I pay attention to for reducing starch loss during cassava starch production?

What should I pay attention to for reducing starch loss during cassava starch production?

-

Common Problems and Solutions During Cassava Starch Production

Common Problems and Solutions During Cassava Starch Production

-

How Does a Cassava Grinder Work?

How Does a Cassava Grinder Work?

-

Advantages of cassava peeler used for cassava agriculture

Advantages of cassava peeler used for cassava agriculture

-

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

What Should You Consider When Ordering a Tapioca Starch Processing Machine?

-

The benefits of hydrocyclone station in starch industrial processes

The benefits of hydrocyclone station in starch industrial processes

-

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

Equipment Solutions for Cassava Chips Processing: Capacity, Applications, and Market Advantages

-

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

Doing Factory Ships High-Quality Garri Processing Equipment to Nigeria

-

Selling High-Quality Cassava Processing Equipment to Uganda

Selling High-Quality Cassava Processing Equipment to Uganda

-

Gari processing line successfully shipped to Nigeria

Gari processing line successfully shipped to Nigeria

-

Cassava starch fine fiber sieve purchased by Indian client

Cassava starch fine fiber sieve purchased by Indian client

-

Gari making plants were transported to Ghana from Henan Jinrui’s factory

Gari making plants were transported to Ghana from Henan Jinrui’s factory

CONTACT US

DOING company offers cassava processing machine from single machine to the complete production line. If you want to get more details about cassava processing machine, please contact us:

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others